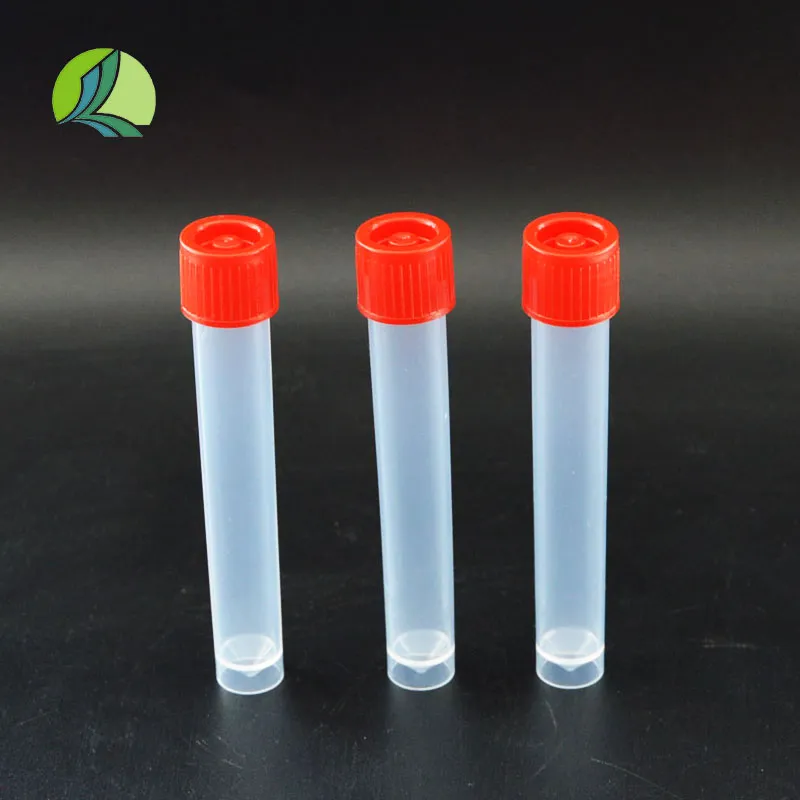

Secure Virus Sample Tubes for Reliable Specimen Collection

The Indispensable Role of Virus Sample Tubes in Modern Diagnostics

In the rapidly evolving landscape of global health and infectious disease management, the integrity and reliability of diagnostic samples are paramount. At the forefront of this critical process is the virus sample tube, a fundamental component ensuring the safe collection, transport, and preservation of viral specimens. These specialized container111s are not merely simple receptacles; they are sophisticated medical devices designed to maintain sample viability, prevent degradation, and safeguard laboratory personnel from potential biohazards. Their role extends beyond simple containment, encompassing precise volumetric accuracy, robust sealing mechanisms, and often, pre-filled viral transport media (VTM or UTM) engineered to stabilize viral nucleic acids for accurate downstream analysis. The demand for high-quality, dependable virus sample tube solutions has surged, driven by widespread testing initiatives, ongoing epidemiological surveillance, and advanced research into new pathogens. For B2B stakeholders in diagnostics, pharmaceuticals, and public health, understanding the nuanced technical specifications, manufacturing precision, and application versatility of these tubes is crucial for optimizing workflow efficiency, enhancing diagnostic accuracy, and ultimately contributing to better patient outcomes and public health security.

This comprehensive guide delves into the intricate details surrounding virus sample tube technology, offering insights into their manufacturing, technical parameters, diverse applications, and the competitive advantages offered by leading manufacturers. We aim to provide B2B decision-makers and technical personnel with the expertise required to make informed procurement and strategic partnership decisions in this vital sector.

The Anatomy of a Virus Sample Tube: Key Components and Design Principles

A modern virus sample tube is a precisely engineered device, far more complex than its appearance suggests. Its design integrates several critical components, each contributing to its overall performance in preserving sample integrity and ensuring safety. Understanding these elements is fundamental to appreciating the tube's role in diagnostics.

- Tube Body: Typically crafted from high-grade, medical-clear polypropylene (PP) or polyethylene (HDPE), the tube body is designed for chemical inertness, ensuring no reaction with the sample or the transport medium. Its optical clarity allows for visual inspection of the sample. Key properties include excellent temperature resistance (from ultra-low freezing temperatures, e.g., -80°C, to ambient conditions) and mechanical strength to withstand handling and centrifugation without cracking or leaking. The volume capacity of the tubes varies, commonly 2mL, 5mL, or 10mL, to accommodate different sample volumes and medium fills.

- Cap: The cap is perhaps the most critical component for maintaining sample integrity and preventing leakage, especially during transport. Screw caps, often made from HDPE, are standard, featuring an internal O-ring or a proprietary sealing lip design that creates a hermetic seal. This leak-proof design is essential for biohazard containment and preventing evaporation or contamination. The cap often includes knurling or a textured surface for easy gripping, even with gloves.

- Transport Medium: Pre-filled virus sample tubes contain a specific viral transport medium (VTM) or universal transport medium (UTM). These formulations are meticulously designed to:

- Preserve Viral Viability: For culture-based assays, the medium maintains the infectivity of the virus.

- Stabilize Nucleic Acids: Crucially for PCR-based molecular diagnostics, the medium prevents the degradation of viral RNA or DNA, often containing stabilizing agents and buffers.

- Inhibit Microbial Growth: Antibiotics and antifungal agents are commonly included to suppress the growth of bacterial and fungal contaminants from the clinical sample, preventing interference with viral detection.

- Inactivate Viruses (Optional): Some advanced media formulations include agents that inactivate infectious viral particles immediately upon collection, reducing biohazard risk during transport and lab processing, while preserving nucleic acid integrity.

- Collection Swabs (Often Included): While not strictly part of the tube, many sample tube kits include sterile collection swabs, typically flocked nylon or polyester, optimized for efficient sample uptake from nasopharyngeal, oropharyngeal, or other sites. The swab shaft is designed to snap off cleanly into the tube.

The synergistic design of these components ensures that a clinical sample, once collected, remains stable, sterile, and diagnostically viable throughout its journey from patient to laboratory, adhering to rigorous standards for patient safety and diagnostic accuracy.

Manufacturing Excellence: A Deep Dive into Production Processes

The production of a high-quality virus sample tube is a sophisticated process demanding meticulous control over materials, manufacturing environments, and quality assurance. Unlike industrial components that might involve casting or forging, these medical devices rely heavily on precision plastic molding, sterile filling, and stringent quality protocols. The process typically unfolds through several key stages:

- Material Selection and Preparation:

The foundation of a reliable virus sample tube lies in the selection of medical-grade raw materials, primarily virgin polypropylene (PP) or high-density polyethylene (HDPE). These polymers are chosen for their inertness, robust mechanical properties, clarity, and resistance to chemicals and temperature extremes. Raw materials undergo rigorous incoming quality control to ensure purity and compliance with industry standards like USP Class VI plastics, confirming their biocompatibility and safety for medical use.

- Precision Injection Molding:

Tube bodies and caps are manufactured using advanced injection molding techniques. This process involves melting the polymer pellets and injecting them under high pressure into precisely engineered molds. The molds themselves are critical, designed with extremely tight tolerances to ensure consistent dimensions, accurate volumetric capacity, and perfect sealing capabilities. Manufacturing occurs in controlled environments, typically ISO Class 7 or Class 8 cleanrooms, to minimize particulate contamination. Automated systems ensure rapid, high-volume production with minimal human intervention, reducing the risk of contamination.

- Viral Transport Medium (VTM/UTM) Formulation and Sterile Filling:

The viral transport medium, a proprietary blend of buffers, cryoprotectants, antibiotics, and sometimes viral inactivating agents, is prepared in a dedicated, highly controlled environment, such as an ISO Class 5 cleanroom. Each batch undergoes stringent quality checks for pH, sterility, and component concentration. Automated filling lines then precisely dispense the specified volume of VTM or UTM into each pre-molded sample tube. This sterile filling process, often employing aseptic techniques, is crucial to prevent microbial contamination of the medium, which could compromise sample integrity or diagnostic results.

- Automated Capping and Sealing:

Immediately after filling, caps are automatically screwed onto the tubes. Advanced capping machines apply precise torque to ensure a consistent, leak-proof seal. This automated process minimizes human contact and ensures uniformity across thousands of tubes for sample collection, preventing any compromise to the sterile environment or the medium's integrity. Robust sealing is paramount to prevent leakage during handling and transport, thereby safeguarding both the sample and personnel from biohazards.

- Sterilization:

Once filled and capped, the assembled virus sample tubes undergo sterilization. Common methods include:

- E-beam (Electron Beam) Sterilization: This method uses high-energy electrons to break down microbial DNA, effectively sterilizing the product. It's a fast, efficient, and residue-free process.

- Gamma Irradiation: Utilizing Cobalt-60, gamma rays penetrate the packaging to eliminate microorganisms. It's highly effective and widely used for medical devices.

- Ethylene Oxide (EtO) Sterilization: While effective, EtO sterilization requires aeration time to dissipate gas residues, making it less common for products with pre-filled media unless specifically validated.

The chosen method ensures a Sterility Assurance Level (SAL) of 10-6, meaning there is less than a one-in-a-million chance of a non-sterile unit.

- Rigorous Quality Control and Testing:

Throughout the entire manufacturing chain, multiple quality control checkpoints are in place. These include:

- Dimensional Accuracy: Verifying tube length, diameter, and cap fit.

- Leak Testing: Pressure differential tests or vacuum tests to ensure the cap provides a hermetic seal.

- Sterility Testing: Batch testing to confirm SAL.

- Medium pH and Composition Analysis: Ensuring the VTM/UTM consistently meets specifications.

- Performance Validation: Testing sample recovery rates and viral stability over specified periods, mimicking real-world transport conditions.

- Traceability: Each batch is traceable back to raw materials and production parameters, a critical aspect of ISO 13485 compliance.

Precision manufacturing in cleanroom environments ensures the integrity and sterility of every virus sample tube.

Adherence to international standards such as ISO 13485 (Quality Management System for Medical Devices), CE marking for European markets, and FDA regulations for the US market is not merely a compliance requirement but a testament to a manufacturer's commitment to producing safe, effective, and reliable virus sample tube products. The expected lifespan of these consumables is dictated by the shelf life of the medium, typically 12-24 months from the date of manufacture, under specified storage conditions.

Technical Parameters and Performance Benchmarks for Virus Sample Tubes

Selecting the appropriate virus sample tube requires a thorough understanding of its technical specifications and performance benchmarks. These parameters directly influence the tube's suitability for specific diagnostic applications, its compatibility with laboratory workflows, and its overall reliability in preserving sample integrity. Below is a detailed table outlining key technical parameters typically associated with high-quality virus sample tubes:

| Parameter | Description/Value |

|---|---|

| Tube Material | Medical-Grade Virgin Polypropylene (PP) or High-Density Polyethylene (HDPE), USP Class VI compliant. |

| Cap Material | HDPE, PP, or Polystyrene (PS), often with an integrated O-ring (e.g., Silicone or TPE). |

| Tube Volume Capacity | Commonly 2 mL, 5 mL, 10 mL; other volumes available for specific applications. |

| Medium Fill Volume | Standard fills: 1 mL, 2 mL, 3 mL, 5 mL (e.g., 3 mL medium in a 10 mL tube). |

| Medium Type | Viral Transport Medium (VTM), Universal Transport Medium (UTM), Saline, or specialized preservation solutions (e.g., nucleic acid stabilization buffer). |

| pH of Medium | Typically maintained within a physiological range, e.g., 7.2 ± 0.2, to preserve viral integrity. |

| Sterilization Method | E-beam (Electron Beam) or Gamma Irradiation. |

| Sterility Assurance Level (SAL) | 10-6 (certified sterile, ready for use). |

| Leak-Proof Design | Validated to IATA standards for biological substance transport (e.g., 95 kPa pressure test). |

| Working Temperature Range | Typical storage: 2-30°C. Transport: -80°C to 40°C (medium dependent for long term). |

| Shelf Life | 12-24 months from manufacturing date, depending on medium and storage conditions. |

| Certifications | ISO 13485:2016, CE Mark (IVD Directive/Regulation), FDA (if applicable), IVDR 2017/746 compliance. |

| Compatibility | Compatible with common downstream molecular assays (qPCR, sequencing) and automated sample processing platforms. |

| Additional Features | Integrated swab, barcoding/QR code for traceability, shatter-proof design, self-standing. |

Performance Benchmarks:

- Sample Stability: A high-performance virus sample tube must demonstrate excellent viral load stability. Studies show that a well-designed VTM can preserve viral RNA/DNA integrity for up to 72 hours at ambient temperature (20-25°C) and for extended periods (e.g., weeks to months) when refrigerated (2-8°C) or frozen (-70°C). This stability is critical for delayed testing or shipment across long distances, ensuring that the detected viral load accurately reflects the patient's condition at the time of collection.

- Viral Inactivation (if applicable): For tubes containing inactivation media, the efficacy of viral inactivation must be validated against relevant pathogens (e.g., SARS-CoV-2, Influenza A/B). This ensures that the sample is rendered non-infectious while preserving nucleic acid integrity, significantly enhancing laboratory safety.

- Reduced Inhibitory Effects: The components of the transport medium and tube material must be validated not to inhibit downstream molecular assays like PCR or RT-qPCR. Inhibitors can lead to false-negative results, a critical concern in diagnostic settings. Reputable manufacturers perform inhibition studies to ensure their products do not interfere with amplification processes.

- Ease of Use and Compatibility: The design of the sample tube should facilitate easy collection and integration into high-throughput automated systems. Features like self-standing designs, clear volume markings, and compatible dimensions for robotic handling systems enhance laboratory efficiency and reduce manual errors. This is particularly relevant when considering `what is a test tube used for` in a high-volume diagnostic context – it's not just a basic vessel, but an integral part of an automated workflow.

These parameters, coupled with adherence to stringent quality management systems like ISO 13485, guarantee that the virus sample tube performs reliably under diverse conditions, delivering consistent and accurate results essential for effective disease surveillance and patient care.

Applications Across the Diagnostic Spectrum

The versatility and critical importance of the virus sample tube extend across a broad array of applications within clinical diagnostics, public health, and research. These specialized `tubes for sample collection` are indispensable wherever viral specimens need to be collected, transported, and preserved for accurate analysis.

- Routine Clinical Diagnostics:

This is the most prevalent application. Virus sample tubes are universally employed for collecting respiratory specimens (nasopharyngeal, oropharyngeal swabs, sputum) for the detection of common viral pathogens such as influenza viruses (Flu A/B), Respiratory Syncytial Virus (RSV), adenoviruses, and human metapneumovirus. During peak seasons, clinical laboratories rely on the consistent performance of these tubes for rapid and accurate diagnosis, which guides patient management and infection control measures.

- Emerging Pathogen Surveillance and Response (e.g., COVID-19):

The global pandemic highlighted the unparalleled importance of high-quality virus sample tubes. They were, and continue to be, the backbone of massive-scale COVID-19 testing initiatives, facilitating the collection and safe transport of SARS-CoV-2 samples from collection sites to testing laboratories. The ability to collect and transport thousands of samples daily, maintaining viral RNA integrity, was crucial for public health surveillance, contact tracing, and epidemic control. The media in these tubes often includes components that inactivate the virus while preserving its genetic material, making handling safer for laboratory personnel without compromising molecular diagnostic accuracy.

- Virology Research and Development:

Academic institutions and pharmaceutical companies utilize virus sample tubes for collecting clinical samples for research purposes, including viral sequencing, drug resistance studies, vaccine efficacy trials, and understanding viral evolution. The consistent performance of these `types of sample collection tubes` ensures that research data is reliable and reproducible, which is fundamental for scientific advancement and drug discovery.

- Public Health Programs and Epidemiology:

Government health agencies and international organizations deploy virus sample tubes in large-scale epidemiological studies and disease surveillance programs. These programs aim to monitor viral prevalence, identify new outbreaks, and track the spread of infectious diseases within communities. The tubes' ability to safely transport samples from remote locations to centralized testing facilities is vital for comprehensive surveillance networks, providing data essential for public health interventions and policy decisions.

- Environmental and Veterinary Diagnostics:

While less common than human diagnostics, specialized `sample tube`s can also be adapted for environmental virus detection (e.g., wastewater surveillance for poliovirus or SARS-CoV-2) or for veterinary diagnostics in animal health, where viral diseases can impact livestock or companion animals. The principles of stable preservation and safe transport remain equally important in these specialized fields.

Virus sample tubes are indispensable tools for clinical diagnostics, facilitating safe and efficient sample collection and transport.

In each of these scenarios, the technical advantages of a superior virus sample tube — its leak-proof design, effective viral transport medium, and robust material — translate directly into practical benefits such as reduced biohazard exposure, minimized sample degradation, improved diagnostic accuracy, and streamlined laboratory workflows. This makes them a critical investment for any entity involved in viral diagnostics or research.

Technological Advantages and Innovations in Virus Sample Tube Design

The design and manufacturing of virus sample tubes are continuously evolving, driven by the need for enhanced safety, improved sample integrity, and greater compatibility with high-throughput laboratory automation. Modern innovations in sample tube technology offer significant advantages over conventional designs, addressing critical pain points in clinical and research settings.

- Advanced Sealing Mechanisms: Beyond simple screw caps, next-generation virus sample tubes often incorporate advanced sealing technologies. These include multi-threaded caps with internal O-rings made from medical-grade silicone or specialized thermoplastic elastomers (TPEs), designed to withstand extreme temperature fluctuations and pressure differentials (e.g., 95 kPa for air transport). This virtually eliminates leakage, providing superior biohazard containment and ensuring sample integrity, crucial for `tubes for sample collection` that must travel long distances.

- Optimized Viral Transport Media (VTM/UTM): Innovations in media formulations are key. Modern VTMs often contain stronger viral inactivating agents that quickly render the virus non-infectious upon contact, significantly improving safety for frontline healthcare workers and laboratory personnel. Simultaneously, these media are engineered to better preserve viral nucleic acids (RNA/DNA) for extended periods at ambient temperatures, reducing the need for immediate refrigeration and simplifying logistics. They also typically include robust buffer systems to maintain optimal pH and potent antibiotic/antifungal cocktails to minimize bacterial and fungal overgrowth, which can interfere with diagnostic assays.

- Enhanced Automation Compatibility: As laboratories move towards higher throughput, the design of the virus sample tube becomes critical for automation. Innovations include standardizing tube dimensions for compatibility with robotic decapping, liquid handling, and nucleic acid extraction systems. Features like self-standing designs, clear fill lines, and optimized tube geometries reduce manual handling steps, minimize the risk of human error, and accelerate processing times, directly impacting laboratory efficiency.

- Integrated Barcoding and Traceability: Many advanced virus sample tubes come pre-labeled with unique 1D or 2D barcodes (QR codes). This integration allows for seamless electronic tracking of samples from the point of collection to final analysis, ensuring comprehensive traceability and reducing transcription errors. This is invaluable for large-scale testing programs and for maintaining stringent quality control in diagnostic workflows.

- Material Innovations for Durability and Clarity: While polypropylene remains standard, ongoing research into polymer science leads to materials with improved optical clarity for visual inspection, enhanced resistance to breakage (even at ultra-low temperatures), and reduced non-specific binding of viral particles to the tube walls. This ensures maximum sample recovery and reduces potential losses during storage or transfer.

- Integrated Swab Design: Many `types of sample collection tubes` are now offered as complete collection kits, featuring flocked swabs that optimize sample collection and release. The swab shaft is designed for easy breakage at a pre-scored point, ensuring the entire collection tip is immersed in the transport medium, preventing cross-contamination and maximizing sample recovery.

Innovative design and advanced materials enhance the performance and safety of modern virus sample tubes.

These technological advancements collectively contribute to a more efficient, safer, and reliable diagnostic process. For B2B buyers, investing in virus sample tubes that incorporate these innovations translates into reduced operational costs, improved diagnostic accuracy, enhanced laboratory safety, and ultimately, better patient care.

Choosing the Right Partner: Manufacturer Comparison and Customization

For B2B entities, selecting the right manufacturer for virus sample tubes is a strategic decision that extends beyond mere product specifications. It involves evaluating a partner's commitment to quality, their manufacturing capabilities, logistical efficiency, and their ability to provide tailored solutions. A thorough comparison can highlight distinct advantages, impacting supply chain reliability and overall operational success.

| Criteria | Manufacturer A (Large Global) | Manufacturer B (Specialized) | WK Packing (Focus on Quality & Service) |

|---|---|---|---|

| Key Certifications | ISO 9001, CE, FDA Registered. | ISO 13485, CE, FDA 510(k) Cleared. | ISO 13485:2016, CE IVD, FDA Registered/Listed. |

| Product Range | Broad, general lab consumables. | Focus on diagnostics, limited customization. | Specialized Virus Sample Tubes & Diagnostic Consumables. |

| Customization Options | Standard offerings, high MOQ for custom. | Moderate, specific media types. | Extensive (custom medium formulation, tube volume, labeling, packaging, barcoding). |

| Manufacturing Capacity | Very High, global scale. | Medium-High. | High & Scalable, modern cleanroom facilities. |

| Lead Time (Standard Orders) | 4-8 weeks (can vary greatly). | 3-6 weeks. | 2-4 weeks (expedited options available). |

| Technical Support | Standard, multi-tier. | Good, product-specific. | Dedicated, responsive 24/7 technical and customer service. |

| R&D and Innovation | Consistent, broad portfolio. | Focused on niche improvements. | Strong commitment to continuous improvement & custom solution development. |

Customized Solutions for Unique Needs:

The "one size fits all" approach rarely applies perfectly in complex diagnostic environments. Recognizing this, leading manufacturers offer extensive customization capabilities for their virus sample tubes. These tailored solutions can provide significant operational advantages:

- Custom Medium Formulations: For specific research protocols or unique diagnostic needs, manufacturers can formulate and fill custom viral transport media. This might involve adjusting pH, adding specific stabilizers, or incorporating different viral inactivating agents to optimize performance for particular viral strains or downstream assays.

- Varied Tube Volumes and Configurations: While standard 2mL, 5mL, and 10mL `types of sample collection tubes` are common, custom volumes or tube designs (e.g., specific cap colors, self-standing versus conical bottoms) can be produced to perfectly integrate with existing laboratory automation platforms or specialized collection protocols.

- Personalized Labeling and Barcoding: Custom printed labels with client logos, specific information fields, or pre-applied 1D/2D barcodes (QR codes) are invaluable for streamlining inventory management, enhancing sample traceability within a laboratory information system (LIS), and reducing manual errors during high-volume testing.

- Tailored Packaging: From bulk sterile packaging to individually wrapped sterile kits (including swab and tube), customization allows clients to optimize their logistics and point-of-care distribution. This includes specific carton counts, multi-kit configurations, or even custom outer packaging for brand recognition.

- Integrated Kit Solutions: Beyond just the tube and medium, a manufacturer can provide a complete sample collection kit, integrating specialized swabs (e.g., nasopharyngeal, oral, or vaginal), patient instructions, biohazard bags, and absorbent pads into a single, convenient package. This simplifies procurement and distribution for large-scale collection efforts.

By partnering with a manufacturer capable of delivering these customized solutions, B2B clients can achieve greater efficiency, reduce operational complexities, and ensure their virus sample tube supply perfectly aligns with their unique scientific and logistical requirements, providing a distinct competitive edge.

Case Studies: Real-World Impact and Success with Virus Sample Tubes

The practical benefits of high-quality virus sample tubes are best illustrated through real-world applications where they have significantly impacted diagnostic efficiency, safety, and reliability. These case studies highlight how superior product design and manufacturing translate into tangible advantages for diverse healthcare and research entities.

Case Study 1: Streamlining High-Throughput COVID-19 Testing for a Regional Diagnostic Lab

Challenge: A major regional diagnostic laboratory faced an overwhelming demand for COVID-19 PCR testing during a peak surge. Their existing virus sample tubes, while functional, presented several bottlenecks: inconsistent capping led to occasional leaks, requiring manual intervention; the media formulation was not optimized for viral inactivation, posing a higher biohazard risk; and the tube dimensions sometimes caused minor issues with their automated liquid handling systems, leading to processing delays.

Solution: The lab switched to a new supplier providing advanced virus sample tubes with a superior, leak-proof screw cap design, pre-filled with an optimized viral inactivation medium. The tubes also featured precision-molded dimensions perfectly compatible with their existing automated decapping and nucleic acid extraction platforms.

Outcome:

- 25% Reduction in Sample Rework: The enhanced leak-proof design virtually eliminated leakage-related sample rejections and manual clean-up, significantly reducing technician workload and improving sample throughput.

- Improved Lab Safety: The viral inactivation medium immediately rendered infectious samples non-viable, drastically lowering the risk of accidental exposure for lab personnel during processing, without compromising PCR results.

- 15% Faster Processing Time per Batch: Seamless integration with automation systems due to precise tube dimensions led to smoother, uninterrupted processing runs, accelerating turnaround times for patient results.

- Enhanced Trust: The consistent quality and reliability of these `sample tube`s boosted confidence among referring physicians and patients in the lab's diagnostic capabilities.

Case Study 2: Enabling Large-Scale Public Health Surveillance in Remote Areas

Challenge: A national public health agency initiated a large-scale influenza surveillance program across diverse geographical regions, including remote areas with limited access to refrigeration. The challenge was to collect, stabilize, and transport thousands of respiratory samples daily to centralized laboratories, ensuring viral RNA integrity despite varying temperatures and extended transit times.

Solution: The agency partnered with a manufacturer specializing in virus sample tubes with advanced UTM formulations designed for extended ambient temperature stability. These `tubes for sample collection` were supplied as complete kits, including flocked swabs and integrated barcodes, simplifying collection and enhancing traceability.

Outcome:

- Reliable Sample Integrity for 72+ Hours: The advanced UTM maintained viral RNA stability for up to 72 hours at 25°C, eliminating the need for cold chain logistics in remote collection sites and reducing transportation costs.

- Enhanced Program Scalability: The ease of use of the pre-filled, barcoded virus sample tube kits allowed for rapid training of community health workers and efficient deployment of collection points, enabling the program to scale rapidly to thousands of samples per day.

- Accurate Epidemiological Data: Consistent sample quality ensured reliable PCR results, providing the public health agency with accurate data for tracking influenza strains, identifying outbreaks, and informing vaccination strategies across the country.

- Reduced Waste and Rework: Fewer compromised samples meant less waste of valuable resources (collection kits, reagents, personnel time) and improved overall cost-effectiveness of the surveillance program.

These case studies underscore the transformative impact that well-engineered virus sample tubes can have on diagnostic operations and public health initiatives, reaffirming their status as foundational components in modern viral diagnostics.

Ensuring Reliability: Quality Assurance and Support

For B2B buyers of virus sample tubes, the decision to partner with a manufacturer extends beyond product specifications to encompass the entirety of their quality management system, customer support, and commitment to reliability. Trustworthiness is built on transparent processes, rigorous standards, and clear commitments.

Stringent Quality Assurance and Control:

A reputable manufacturer of virus sample tubes operates under a comprehensive Quality Management System (QMS) compliant with international medical device standards, primarily ISO 13485:2016. This certification is critical as it outlines requirements for a QMS where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements. Key aspects include:

- Raw Material Inspection: Every batch of polypropylene, HDPE, and chemical components for the VTM is rigorously inspected upon arrival to ensure it meets predefined purity, consistency, and biocompatibility standards (e.g., USP Class VI).

- In-Process Monitoring: Throughout injection molding, medium preparation, filling, and capping, continuous monitoring systems (e.g., visual inspections, automated leak detection, volumetric checks) are in place to identify and correct deviations immediately.

- Final Product Testing: Each batch of finished virus sample tubes undergoes comprehensive testing, including sterility assurance level (SAL 10-6) validation, leak-proof integrity (e.g., 95 kPa pressure test), pH stability of the medium, and real-time/accelerated shelf-life studies to confirm viral nucleic acid preservation capabilities.

- Cleanroom Environment Control: Manufacturing facilities maintain ISO-certified cleanroom conditions (e.g., ISO Class 7 or 8 for tube molding, ISO Class 5 for media filling) with strict control over air particulate levels, temperature, humidity, and personnel gowning protocols.

- Full Traceability: Robust lot numbering and batch record systems ensure complete traceability from the final product back to specific raw material lots, production dates, and quality control personnel. This is vital for recall management and continuous improvement.

Customer Support and Service Commitments:

Beyond product quality, a reliable partner provides comprehensive support infrastructure:

- Delivery Cycle and Logistics: Clear communication regarding lead times, which typically range from 2-4 weeks for standard orders, with provisions for expedited delivery in urgent scenarios. Efficient global logistics networks ensure timely and safe delivery of large volumes of `tubes for sample collection`.

- Warranty and Quality Guarantee: Reputable manufacturers offer product warranties covering manufacturing defects and performance as per specifications for the stated shelf life. This includes a commitment to replace or refund products that do not meet quality standards.

- Dedicated Technical Support: Access to experienced technical support teams who can provide guidance on product usage, troubleshooting, validation protocols, and integration with specific laboratory workflows. This direct line to expertise is invaluable for optimizing operations and resolving any issues swiftly.

- Post-Market Surveillance: An effective system for collecting and responding to customer feedback, complaints, and adverse events ensures continuous product improvement and regulatory compliance.

Frequently Asked Questions (FAQ):

- Q1: What is a sample tube used for in viral diagnostics?

- A: A sample tube, specifically a virus sample tube, is primarily used for the collection, secure transport, and preservation of biological specimens containing viral particles (e.g., nasopharyngeal swabs, saliva) from the point of collection to the laboratory for diagnostic testing, such as PCR or viral culture. Its pre-filled medium stabilizes viral nucleic acids and often inactivates infectious agents.

- Q2: What are the main `types of sample collection tubes` available for viruses?

- A: The primary types include: Viral Transport Medium (VTM) tubes, which preserve viral viability for culture; Universal Transport Medium (UTM) tubes, a more general-purpose medium suitable for both viral and chlamydial specimens; Nucleic Acid Preservation tubes, which contain a buffer that immediately lyses cells and stabilizes nucleic acids for molecular testing while inactivating viruses; and plain Dry Swab tubes, for specific applications where no medium is required immediately after collection.

- Q3: How should a virus sample tube be stored?

- A: Unused virus sample tubes with media should typically be stored at room temperature (2-30°C or 2-25°C, depending on manufacturer specifications) in their original packaging, away from direct sunlight. Once a sample is collected, it should be transported and processed as quickly as possible. If immediate processing is not feasible, the sample should be refrigerated (2-8°C) for up to 72 hours. For longer storage, samples should be frozen at -70°C or colder.

- Q4: What is the shelf life of the medium in a virus sample tube?

- A: The shelf life of the viral transport medium typically ranges from 12 to 24 months from the date of manufacture, provided the tubes are stored under recommended conditions. It's crucial to check the expiry date printed on each tube or kit.

- Q5: Are virus sample tubes compatible with automated laboratory systems?

- A: High-quality virus sample tubes are increasingly designed for compatibility with automated laboratory systems, including robotic decappers, liquid handlers, and nucleic acid extraction platforms. Manufacturers often provide documentation or validation data to confirm compatibility, which is a significant advantage for high-throughput diagnostic labs.

- Q6: What is the difference between VTM and UTM?

- A: While often used interchangeably, VTM (Viral Transport Medium) is specifically formulated for the transport and preservation of viruses for viral culture and molecular testing. UTM (Universal Transport Medium) is a broader medium designed for transporting various pathogenic microorganisms, including viruses, chlamydia, mycoplasma, and ureaplasma. Both are generally suitable for molecular viral diagnostics, but VTM may have optimized components for specific viral viability requirements.

These robust quality frameworks and customer-centric support systems are fundamental to building long-term, trustworthy partnerships in the B2B medical consumables sector.

Conclusion: The Foundation of Reliable Viral Diagnostics

The virus sample tube stands as a testament to precision engineering and scientific innovation, forming the critical initial link in the diagnostic chain for infectious diseases. Its seemingly simple form belies a complex design and manufacturing process, optimized to ensure the safe collection, stable preservation, and efficient transport of viral specimens. From robust materials and leak-proof seals to advanced viral transport media that maintain nucleic acid integrity and enhance safety, every aspect of a high-quality virus sample tube contributes directly to the accuracy of diagnostic results and the safety of healthcare professionals.

For B2B stakeholders across clinical laboratories, public health agencies, and research institutions, investing in superior virus sample tube solutions is not merely a procurement decision but a strategic imperative. It reduces biohazard risks, minimizes sample degradation and re-collection rates, streamlines high-throughput workflows through automation compatibility, and ultimately contributes to more reliable disease surveillance and effective patient management. As the world continues to face the challenges of emerging and re-emerging infectious diseases, the demand for innovative, high-performance virus sample tubes will only grow. Partnering with a manufacturer committed to stringent quality control (such as ISO 13485 certification), continuous innovation, and responsive customer support is paramount to securing a dependable supply chain and achieving operational excellence in viral diagnostics.

In an era where rapid and accurate viral detection is crucial for global health security, the virus sample tube remains an unsung hero, underpinning the diagnostic capabilities that protect communities and save lives.

References

- World Health Organization. (2020). Laboratory testing for coronavirus disease 2019 (COVID-19) in suspected human cases: interim guidance.

- Centers for Disease Control and Prevention. (2023). Interim Guidelines for Collecting, Handling, and Testing Clinical Specimens for COVID-19.

- International Organization for Standardization. (2016). ISO 13485:2016 Medical devices — Quality management systems — Requirements for regulatory purposes.

- Loeffelholz, M. J., & Tang, Y. W. (2020). Laboratory diagnosis of emerging respiratory viruses. Journal of Clinical Microbiology, 58(4), e00302-20.

- Clinical and Laboratory Standards Institute. (2020). M40-A2: Quality Control of Microbiological Transport Systems; Approved Guideline—Second Edition.

- Basile, R. A., Boudreau, R. M., & Walsh, M. (2020). Comparison of three viral transport media for detection of SARS-CoV-2 by reverse transcription–quantitative PCR. Journal of Clinical Microbiology, 58(8), e00782-20.

-

Aesthetic Makeup Spray Bottles | Fine Mist Empty RefillableNewsAug.19,2025

-

White Plastic Veterinary Vaccine Vials | Lab Liquid BottlesNewsAug.18,2025

-

Plastic Medicine Liquid Bottle: Secure Flip Top Drug VialsNewsAug.17,2025

-

Durable 250ml Blue Plastic Vaccine Vial for Lab & Vet UseNewsAug.16,2025

-

Sterile Virus Sample Tubes: Secure & Reliable Specimen CollectionNewsAug.15,2025