Sterile Virus Sample Tubes: Secure & Reliable Sample Collection

Introduction to Advanced Viral Sample Collection

In the realm of modern diagnostics and public health, the integrity and reliability of biological sample collection are paramount. Central to this critical process is the virus sample tube, a specialized container engineered for the safe and effective transport and preservation of viral specimens. These specialized tubes are not merely passive containers; they are sophisticated medical devices designed to maintain sample viability, prevent degradation, and ensure accurate downstream laboratory analysis. This article delves into the technical intricacies, industry trends, and application-specific advantages of these essential components in the healthcare ecosystem, providing insights for B2B decision-makers and technical professionals.

The evolution of diagnostic technologies, especially in virology, has placed stringent demands on sample collection methodologies. The primary function of a high-quality virus sample tube is to stabilize the viral genetic material (RNA or DNA) immediately after collection, inactivating the virus while preserving its nucleic acid integrity. This is achieved through meticulously formulated Viral Transport Medium (VTM) or Universal Transport Medium (UTM), which often contain antimicrobial agents to inhibit bacterial and fungal contamination, and protein stabilizers to protect viral components. Understanding the precise engineering and rigorous quality control behind these tubes is crucial for ensuring the fidelity of diagnostic results.

Current Industry Trends in Viral Sample Collection

The landscape of viral diagnostics is continually evolving, driven by emerging pathogens, technological advancements, and the demand for faster, more accurate, and more accessible testing. Key trends influencing the development and deployment of the virus sample tube include:

- Enhanced Sample Stability: A growing focus on transport media that offer extended stability at wider temperature ranges, reducing the need for immediate refrigeration and facilitating logistics in diverse environments. Innovations in VTM formulations are designed to maintain viral RNA integrity for up to 72 hours at refrigerated temperatures (2-8°C) and often for shorter periods at ambient temperatures.

- Automation Compatibility: Tubes are increasingly designed with standardized dimensions and features that facilitate automated processing in high-throughput laboratories. This includes compatibility with automated decappers, liquid handlers, and nucleic acid extraction platforms, significantly improving efficiency and reducing manual handling errors.

- Non-Inactivating Transport Media: While inactivating VTMs are common, there's a niche demand for non-inactivating media for applications requiring live virus culture, such as antimicrobial resistance testing or vaccine research. These require even stricter biosafety protocols.

- Sustainability and Waste Reduction: The medical device industry is increasingly pressured to adopt more sustainable manufacturing practices. This translates to exploring recyclable materials for the tube itself, and packaging solutions that minimize environmental impact without compromising sterility or performance.

- Integrated Swabs and Collection Kits: The trend towards complete, ready-to-use collection kits, where the sterile swab is pre-packaged with the sample tube and VTM, streamlines the collection process and minimizes contamination risks. The "flocked" swab design, which efficiently collects and releases samples, has become a gold standard.

These trends collectively push manufacturers to innovate constantly, ensuring that the tubes for sample collection meet the rigorous demands of global health challenges and advanced diagnostic protocols.

Manufacturing Process Flow of Virus Sample Tubes

The production of a high-quality virus sample tube is a complex, multi-stage process requiring stringent environmental controls, precision engineering, and rigorous quality assurance. It ensures the sterility, structural integrity, and biological compatibility crucial for diagnostic accuracy.

-

Material Selection:

The primary materials for the tube itself are typically medical-grade polypropylene (PP) or polystyrene (PS) due to their excellent chemical inertness, optical clarity, and robust mechanical properties. Caps are often made from high-density polyethylene (HDPE) or PP, chosen for their secure sealing capabilities and resistance to cracking. Flocked swabs utilize a nylon fiber tip with an acrylonitrile butadiene styrene (ABS) or polypropylene shaft. These materials must be non-cytotoxic and free from PCR inhibitors.

-

Tube and Cap Molding (Injection Molding):

Tubes and caps are produced via high-precision injection molding in ISO Class 7 or 8 cleanroom environments. Granular polymer resin is heated and injected under high pressure into precisely engineered molds. This process ensures consistent dimensions, wall thickness, and thread integrity for secure sealing. Modern molding techniques minimize flash and ensure smooth surfaces for optimal sample flow and reduced protein binding.

-

Swab Manufacturing:

Flocked swabs are created by electrostatically charging nylon fibers and adhering them perpendicularly to the tip of a molded plastic shaft using a medical-grade adhesive. This creates a soft, absorbent brush-like tip capable of efficiently collecting and releasing cellular material.

-

Viral Transport Medium (VTM) Preparation:

VTM is typically prepared in a controlled pharmaceutical environment. It consists of a balanced salt solution (e.g., Hanks' Balanced Salt Solution), protein stabilizers (e.g., Bovine Serum Albumin), antibiotics (e.g., penicillin, streptomycin, amphotericin B) to inhibit bacterial and fungal growth, and buffering agents (e.g., HEPES) to maintain a stable pH. Each batch undergoes rigorous quality control for sterility, pH, and performance validation.

-

VTM Dispensing and Filling:

Using automated, sterile filling lines in a cleanroom, precise volumes of VTM are dispensed into each tube. This process is meticulously controlled to prevent contamination and ensure consistent fill volumes, critical for accurate sample dilution ratios.

-

Assembly and Sealing:

Caps are securely screwed onto the filled tubes, often using automated torque control systems to ensure a leak-proof seal without over-tightening. In integrated kits, the swab is also assembled with the tube, typically with a break-point shaft for easy sample insertion.

-

Sterilization:

The assembled tubes (with or without VTM, depending on the sterilization method) undergo terminal sterilization. Common methods include Gamma irradiation or Ethylene Oxide (EtO) sterilization. These processes are validated to achieve a sterility assurance level (SAL) of 10-6, meaning less than one non-sterile unit in a million. Sterilization records are meticulously maintained.

-

Packaging and Labeling:

Sterilized tubes are individually wrapped or packaged in sterile pouches, then boxed. Labeling includes product name, batch number, expiration date, sterilization method, and regulatory compliance marks (e.g., CE, FDA). This ensures traceability and compliance with global standards.

-

Quality Control and Testing Standards:

Throughout the process, rigorous QC checks are performed. These include: dimensional accuracy (ISO 286), leak-proof testing (e.g., for UN3373 compliance for diagnostic specimens), sterility testing (USP <71>), VTM pH verification, microbial growth promotion, cytotoxicity testing (ISO 10993), and performance validation with control viruses. Compliance with ISO 13485 (Medical Devices Quality Management Systems) and FDA QSR (Quality System Regulation) is essential.

The robust manufacturing process ensures that each sample tube delivers optimal performance and reliability in diverse clinical and research settings. The service life of these tubes, primarily dictated by the stability of the VTM, typically ranges from 12 to 24 months when stored under recommended conditions.

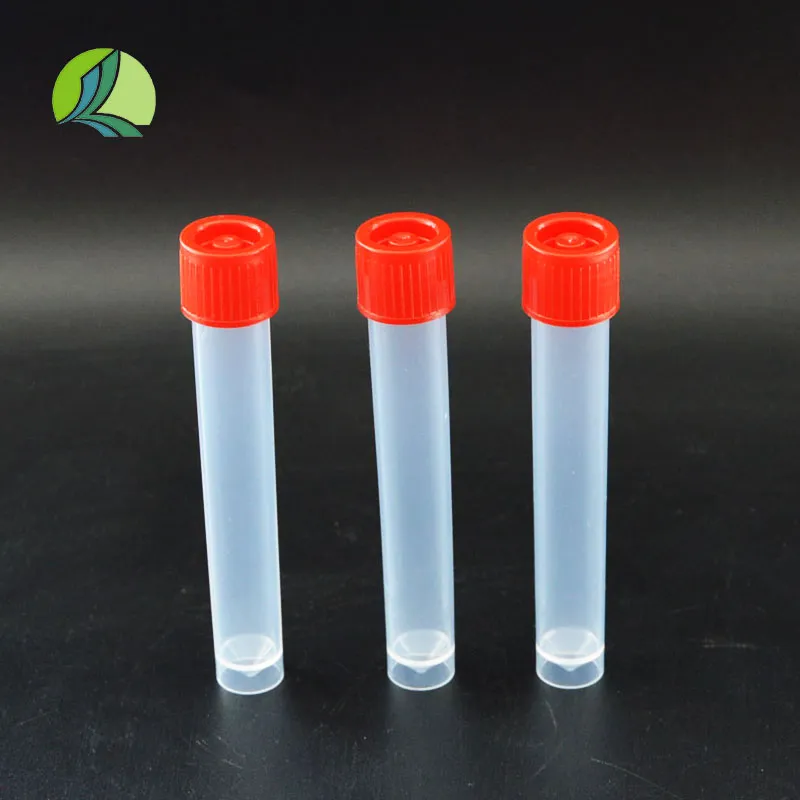

Figure 1: High-precision molding of the virus sample tube component ensuring dimensional accuracy.

Technical Specifications and Parameters

The technical specifications of a virus sample tube are critical for its performance and compatibility with laboratory workflows. These parameters ensure consistency, safety, and efficacy across various diagnostic platforms.

| Parameter | Specification | Relevance / Standard |

|---|---|---|

| Tube Material | Medical-grade Polypropylene (PP) or Polystyrene (PS) | Biocompatibility, chemical inertness, durability (ISO 10993) |

| Cap Material | High-Density Polyethylene (HDPE) or Polypropylene (PP) | Leak-proof seal, chemical resistance |

| Tube Dimensions (e.g., Diameter x Length) | 16x100mm, 13x85mm (common sizes), or customized | Compatibility with automated systems, centrifuge compatibility |

| Volume (Tube) | 5mL, 10mL (common), or customized | Adequate sample collection volume |

| VTM Volume | 2mL or 3mL (standard), or customized | Optimal sample-to-medium ratio for viral stability |

| VTM Composition | Balanced Salt Solution, Protein Stabilizers, Antibiotics, pH Buffers | Viral inactivation (if applicable), RNA/DNA preservation, microbial inhibition |

| Sterility Assurance Level (SAL) | 10-6 | Ensures aseptic collection, critical for diagnostic accuracy (ISO 11137, ISO 11135) |

| Leakage Test Compliance | 95kPa pressure differential (liquid tight) | Safe transport of biological substances (UN3373, IATA) |

| Shelf Life | 12-24 months from manufacturing date | Stability of VTM and components |

| Operating Temperature Range (Transport) | 2-8°C recommended; Ambient (up to 25°C) for short periods | Preservation of viral nucleic acids |

These specifications are carefully chosen and rigorously tested to ensure that the tubes for sample collection provide a stable and secure environment for viral specimens from the point of collection to laboratory analysis.

Technical Advantages of High-Quality Virus Sample Tubes

Superior design and manufacturing confer significant technical advantages to premium virus sample tube products, directly impacting diagnostic accuracy and operational efficiency.

- Optimized Viral Nucleic Acid Preservation: The meticulously formulated VTM rapidly inactivates the virus while effectively stabilizing viral RNA/DNA, preventing degradation by nucleases. This ensures high-quality nucleic acid extraction, crucial for sensitive molecular tests like PCR and next-generation sequencing.

- Enhanced Sample Recovery with Flocked Swabs: Flocked swabs significantly outperform traditional fiber-wound swabs in sample collection and release. The unique perpendicular nylon fibers create a soft brush that efficiently collects a large number of cells and, more importantly, releases over 95% of the collected sample into the VTM, maximizing diagnostic yield.

- Superior Leak-Proof Design: Precision-engineered caps with multi-start threads and integrated O-rings or self-sealing gaskets ensure a robust, leak-proof seal, even under varying temperature and pressure conditions during transport. This adherence to UN3373 packaging requirements safeguards personnel and prevents sample loss or cross-contamination.

- Sterility and Aseptic Handling: Each sample tube and its components are terminally sterilized and packaged to maintain an aseptic environment. This prevents exogenous microbial contamination that could interfere with downstream molecular assays or compromise viral culture.

- Automation Compatibility and Workflow Efficiency: Standardized tube dimensions, clear graduations, and robust construction facilitate seamless integration into automated laboratory systems, including robotic liquid handlers and nucleic acid extraction platforms. This reduces manual labor, minimizes human error, and accelerates sample processing.

- Broad Spectrum Antimicrobial Protection: The VTM typically includes a cocktail of antibiotics and antifungals, inhibiting the growth of commensal bacteria and fungi from the collection site. This prevents overgrowth that could outcompete viruses or interfere with PCR assays.

- Temperature Resilience: Advanced VTM formulations offer improved stability across a wider range of temperatures, extending sample viability during transport and storage, which is critical for logistics in remote or resource-limited areas.

Figure 2: Ergonomic design and secure sealing of a typical virus sample tube kit.

Application Scenarios for Virus Sample Tubes

The versatility and reliability of the virus sample tube make it indispensable across a multitude of clinical, research, and public health applications. These tubes are essentially what is a test tube used for in modern virology, offering tailored solutions for diverse needs.

- Clinical Diagnostics: Essential for collecting samples for PCR-based detection of respiratory viruses (e.g., SARS-CoV-2, influenza, RSV), gastrointestinal viruses (e.g., Norovirus), and other infectious agents. They are foundational for rapid diagnosis, guiding treatment decisions, and preventing disease spread in hospitals, clinics, and emergency rooms.

- Epidemiological Surveillance and Public Health: Critical for monitoring the prevalence and spread of infectious diseases in populations. Public health agencies rely on consistent and reliable sample tube collection to track outbreaks, identify new variants, and inform public health interventions. Large-scale testing initiatives, such as those during pandemics, heavily depend on the availability and performance of these tubes.

- Research and Development: Used extensively in virology research for culturing viruses, studying viral replication mechanisms, developing new diagnostic assays, and testing antiviral compounds. Researchers require tubes that offer pristine sample integrity for complex molecular analyses.

- Drug and Vaccine Development: Integral to clinical trials for new antiviral therapies and vaccines. Samples collected in these tubes are used to assess viral load changes, immune responses, and vaccine efficacy.

- Biobanking: High-quality tubes for sample collection are suitable for long-term storage of viral specimens in biobanks, supporting future research and retrospective studies, especially when cryopreserved under appropriate conditions.

- Veterinary Diagnostics: Beyond human health, these tubes find application in veterinary medicine for diagnosing viral infections in animals, which is crucial for animal welfare and preventing zoonotic disease transmission.

Their robust design and effective preservation capabilities ensure the highest standards in diverse diagnostic and research environments, from high-volume clinical labs to remote field collection points.

Vendor Comparison: Key Differentiators in Virus Sample Tube Procurement

Choosing the right supplier for virus sample tube products is a strategic decision for healthcare providers, diagnostic labs, and research institutions. While many manufacturers offer similar products, key differentiators significantly impact product quality, reliability, and cost-effectiveness.

| Feature/Criterion | Tier 1 Manufacturer (e.g., WK Packing) | Standard Manufacturer |

|---|---|---|

| Certifications & Regulatory Compliance | ISO 13485, CE IVD, FDA 510(k) cleared, Medical Device Directive (MDD) / In Vitro Diagnostic Regulation (IVDR) compliant, UN3373 packaging. | Basic ISO 9001, possibly CE marking. May lack specific medical device or transport certifications. |

| VTM Formulation & Stability | Proprietary, optimized formulation with validated viral inactivation/preservation, extended stability (72h+ at 2-8°C, certain ambient resilience), non-inhibitory to PCR. | Standard formulation, potentially shorter stability, less data on PCR compatibility. |

| Tube & Cap Design Integrity | Precision injection molding (medical-grade virgin polymers), secure multi-start thread, leak-proof at 95kPa, minimal protein binding, optical clarity. | May use recycled plastics, less consistent thread quality, potential for minor leakage, lower optical clarity. |

| Swab Performance | High-quality flocked nylon, ergonomic design, high collection/release efficiency (>95%), sterile, break-point shafts. | Standard fiber-wound cotton/rayon, lower release efficiency, potential for shedding, inferior material. |

| Sterilization Method | Validated Gamma Irradiation or Ethylene Oxide (EtO) with SAL 10-6. Full traceability. | May use less validated methods or lack comprehensive SAL data. |

| Automation Compatibility | Designed for automated systems (liquid handlers, decappers, extractors), consistent dimensions, barcoding options. | Variable compatibility, may require manual intervention. |

| Technical Support & Customization | Dedicated technical support, R&D capabilities for custom VTM/tube designs, flexible packaging/labeling. | Limited support, off-the-shelf products only. |

A thorough vendor assessment focusing on these criteria ensures long-term reliability and minimizes potential risks associated with compromised sample integrity, which can have significant downstream consequences for patient care and research outcomes.

Customized Solutions for Viral Sample Collection

Recognizing the diverse and evolving needs of diagnostics and research, leading manufacturers offer extensive customization options for these advanced sample tube solutions. These tailored solutions ensure optimal performance for specific applications or integration into unique workflows.

- VTM Formulation Customization: Adjustments to the transport medium composition, such as varying antibiotic concentrations, adding specific stabilizers for unique viral targets, or developing non-inactivating media for live virus studies. This also includes different pH buffer systems or dyes for visual identification.

- Tube Dimensions and Material Modifications: Production of tubes with specific lengths, diameters, or volumes to fit specialized racks, automated systems, or existing centrifuge rotor capacities. Custom colors or transparency levels for specific optical requirements are also possible. Alternative materials for enhanced chemical resistance or reduced protein binding can be explored.

- Cap Design and Sealing Mechanisms: Development of caps with specific thread profiles, internal seals (e.g., septa for piercing), or even flip-top designs for rapid access. This ensures compatibility with varied handling protocols and equipment.

- Integrated Swab Options: Offering different swab types (e.g., nasopharyngeal, oropharyngeal, anterior nasal, saliva collection), varying shaft lengths, or specific breakpoint designs to suit different collection sites and user preferences. Some solutions include saliva collection kits with funnels integrated.

- Labeling and Barcoding: Custom printed labels with client logos, specific information fields, or pre-applied 1D/2D barcodes for seamless integration into laboratory information management systems (LIMS) and enhanced traceability.

- Kit Configuration: Assembling the sample tube with additional components such as patient instructions, biohazard bags, absorbent pads, or multiple swabs to create complete, ready-to-use kits tailored for specific testing programs or geographical regions.

Engaging with a manufacturer that possesses strong R&D capabilities and a flexible production line, like WK Packing, allows for the development of bespoke solutions that precisely address complex operational requirements, ultimately enhancing diagnostic accuracy and workflow efficiency.

Application Case Studies

Real-world applications underscore the critical role and reliable performance of high-quality tubes for sample collection.

Figure 3: A comprehensive kit featuring a virus sample tube with integrated swab for efficient collection.

Case Study 1: Large-Scale Pandemic Testing Initiative

During a recent global pandemic, a national health agency implemented a vast testing program requiring millions of viral samples to be collected and processed daily. The agency partnered with a leading manufacturer of viral transport media and collection devices, WK Packing, known for its robust production capacity and adherence to international quality standards. The chosen tubes featured a proprietary VTM formulation designed for extended viral RNA stability at ambient temperatures for up to 48 hours, significantly easing logistical burdens in remote collection sites lacking immediate refrigeration. The tubes were also optimized for robotic decapping and liquid handling systems, allowing for high-throughput processing in centralized laboratories. This enabled the agency to scale up testing capacity rapidly, achieving over 99.8% sample integrity rates from collection to PCR analysis, playing a pivotal role in public health surveillance and intervention strategies. The reliable leak-proof design ensured safe transport of millions of specimens, complying with stringent UN3373 regulations.

Case Study 2: Research Study on Emerging Viral Pathogens

A university research consortium undertaking a multi-year study on emerging viral pathogens required specialized sample tube kits capable of preserving highly labile viral RNA from diverse environmental and clinical sources. They required custom VTM volumes and specific, non-inhibitory formulations for subsequent next-generation sequencing (NGS) and culturing experiments. WK Packing collaborated closely with the researchers to develop a customized solution: tubes with an adjusted VTM pH, specific protein stabilizers to prevent RNA degradation over prolonged cold storage, and non-flocked cotton swabs to minimize potential PCR inhibitors in specific environmental matrices. The customized kits were delivered sterile and pre-aliquoted, reducing preparation time for the research teams and ensuring consistency across thousands of samples. This customization directly contributed to the high success rate of viral RNA recovery and subsequent gene sequencing, leading to several high-impact publications on novel viral variants.

Ensuring Quality and Reliability: EEAT Compliance (Authoritativeness)

Authoritativeness in the manufacture and supply of advanced sample tube products is built upon a foundation of stringent quality management, rigorous testing, and adherence to international regulatory standards.

- Certifications: Manufacturers like WK Packing operate under ISO 13485 (Medical Devices Quality Management Systems) certification, demonstrating a comprehensive quality system for the design, development, production, and distribution of medical devices. Products are typically CE IVD marked, indicating compliance with European In Vitro Diagnostic Device Regulations, and may hold FDA 510(k) clearance for the US market.

- Partnerships: Collaboration with leading diagnostic companies, public health laboratories, and research institutions globally validates the quality and performance of these tubes in real-world, high-stakes environments. Long-standing partnerships reflect consistent product excellence and reliability.

- Years of Service & Expertise: Decades of experience in medical device manufacturing translate into deep technical expertise in material science, cleanroom production, and VTM formulation, ensuring robust product design and consistent quality.

- Authoritative References: Compliance with international standards such as ISO 11137 (Sterilization of health care products — Radiation), ISO 11135 (Sterilization of health care products — Ethylene oxide), and UN3373 (Packaging instructions for biological substances, Category B) for safe transport. The VTM formulations are often based on CDC or WHO guidelines.

- Test Data & Validation: Every batch of sample tube products undergoes extensive quality control testing, including sterility tests (USP <71>), leak tests (e.g., 95 kPa pressure differential), cytotoxicity tests (ISO 10993), and performance validation tests using attenuated viral controls to confirm nucleic acid stability and recovery rates. Comprehensive documentation and Certificates of Analysis are available for full traceability.

This commitment to verifiable quality and adherence to global standards builds trust and establishes strong authoritativeness in the highly regulated medical device market.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between VTM and UTM?

A: Both VTM (Viral Transport Medium) and UTM (Universal Transport Medium) are designed for viral sample collection. Historically, VTM specifically indicated a medium for viruses, while UTM was a broader term covering various pathogens. In practice, the terms are often used interchangeably today, with formulations typically containing antibiotics, antifungals, and stabilizers to preserve viral nucleic acids and inhibit microbial growth.

Q: How long can samples be stored in a sample tube before testing?

A: Samples in VTM/UTM can typically be stored at 2-8°C for up to 72 hours (3 days) without significant loss of viral nucleic acid integrity. For longer-term storage, samples should be frozen at -70°C or colder. Always refer to the manufacturer's specific instructions and validation data for optimal storage conditions and times.

Q: Are these tubes for sample collection compatible with automated nucleic acid extraction systems?

A: Yes, high-quality virus sample tubes are designed with standardized dimensions to be compatible with most common automated nucleic acid extraction platforms and liquid handling systems. It is recommended to verify compatibility with your specific instrumentation, and leading vendors often provide validation data for common platforms.

Q: What certifications should I look for when sourcing sample tube products?

A: Key certifications include ISO 13485 (Medical Devices Quality Management Systems), CE IVD (for European markets), and potentially FDA 510(k) clearance (for the US market). For safe transport, look for compliance with UN3373 packaging instructions and IATA Dangerous Goods Regulations. Sterilization certificates (e.g., ISO 11137) are also crucial.

Logistics and Support: Ensuring Trustworthiness

Reliable supply chain, clear commitments, and robust customer support are foundational to trustworthiness in B2B partnerships for medical devices.

- Lead Time and Fulfillment: Efficient manufacturing processes and established logistics networks ensure prompt order fulfillment. Standard lead times for common sample tube configurations typically range from 2-4 weeks, depending on order volume and customization. Expedited options may be available for urgent requirements. WK Packing maintains strategic inventory levels and robust production lines to meet demand fluctuations.

- Warranty Commitments: Products typically come with a warranty covering manufacturing defects and ensuring compliance with stated specifications for the duration of their shelf life. Specific warranty terms will be outlined in supply agreements, providing assurance against material or functional failures under normal use.

- Customer Support: Comprehensive after-sales support includes dedicated account managers, technical support specialists for product inquiries, troubleshooting, and assistance with integration. Access to detailed product documentation, Certificates of Analysis, and regulatory compliance files is readily available. Training for proper usage and handling can also be provided.

- Global Distribution Network: A well-established global distribution network ensures that tubes for sample collection can be delivered efficiently and reliably to clients worldwide, adhering to international shipping regulations for biological substances.

This holistic approach to logistics and support reinforces the trustworthiness of the supplier, fostering long-term collaborative relationships crucial for public health and research initiatives.

Conclusion

The specialized sample tube is a critical, yet often underestimated, component in the complex ecosystem of modern diagnostics and public health. Its sophisticated design, coupled with advanced manufacturing processes and stringent quality controls, ensures the integrity of viral specimens from the point of collection to laboratory analysis. As viral pathogens continue to challenge global health, the demand for highly reliable, efficient, and technologically advanced sample collection solutions will only intensify. Partnering with a reputable manufacturer, such as WK Packing, committed to innovation, quality, and comprehensive support, is essential for institutions aiming to achieve the highest standards in viral diagnostics and research.

References

- World Health Organization. Laboratory testing for coronavirus disease (COVID-19) in suspected human cases: Interim guidance. WHO/COVID-19/laboratory/2020.6. Available from: https://www.who.int/publications/i/item/laboratory-testing-for-coronavirus-disease-(covid-19)-in-suspected-human-cases

- Centers for Disease Control and Prevention. Interim Guidelines for Collecting, Handling, and Testing Clinical Specimens for COVID-19. Available from: https://www.cdc.gov/coronavirus/2019-ncov/lab/guidelines-clinical-specimens.html

- International Organization for Standardization. ISO 13485:2016 Medical devices — Quality management systems — Requirements for regulatory purposes. Available from: https://www.iso.org/standard/59752.html

- International Air Transport Association. Dangerous Goods Regulations (IATA DGR). Available from: https://www.iata.org/en/publications/dgr/

- United Nations Recommendations on the Transport of Dangerous Goods, Model Regulations (UN3373). Available from: https://unece.org/transport/dangerous-goods/un-model-regulations-rev21

-

High-Quality Polypropylene Falcon Tubes | 15ml & 50ml ConicalNewsAug.27,2025

-

Secure Virus Sample Tubes for Reliable Specimen CollectionNewsAug.21,2025

-

Aesthetic Makeup Spray Bottles | Fine Mist Empty RefillableNewsAug.19,2025

-

White Plastic Veterinary Vaccine Vials | Lab Liquid BottlesNewsAug.18,2025

-

Plastic Medicine Liquid Bottle: Secure Flip Top Drug VialsNewsAug.17,2025