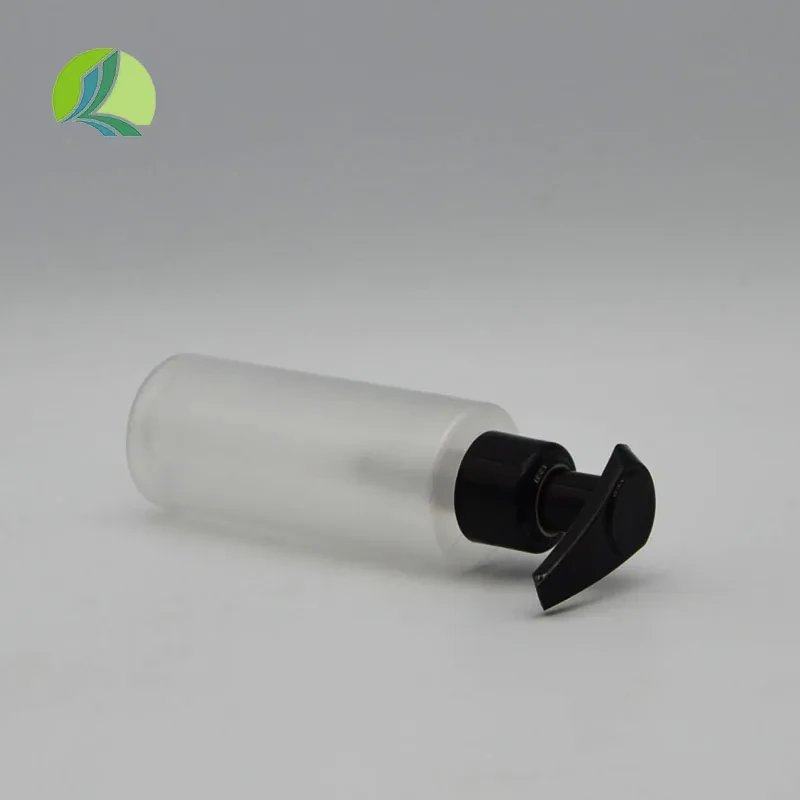

Animal Laboratory Liquid Bottle White Plastic Veterinary Medicine Vaccine Bottle Pp 500ml

As a special packaging for animal vaccines, it mainly uses the following processing processes

Injection blowing process:

The injection blow molding process first uses the injection machine to inject the molten plastic into the injection mold to form the tube blank, and the tube blank is formed on the hollow punch with microholes around the wall; Then transfer to the blow mold while it is hot; Then the mold is closed and compressed air is passed through the pipe of the mandrel to make the mold billet blow and stick to the cavity wall of the mold. Finally, the compressed air is released and the plastic parts are taken out after pressure holding and cooling. The injection and blowing process does not require secondary processing, and the veterinary vaccine vial has stable quality, no scraps and flash edges, and good appearance, but it can not be used for the production of large parts and parts with handles.

Extrusion and blowing process: extrusion and blowing process is the process of using the extruder to extrude the blank through the ring die of the machine head, and then the blank is transferred into the blow mold to expand into the hollow product. According to the forming of different types of products in actual production, the extruding-blow molding process has different implementation methods, such as single-layer direct protection billet - blow molding, multi-layer co-extrusion billet - blow molding extruding-accumulation-compact billet - blow molding and extrusion billet - stretch - blow molding.

PET injection and blow molding process: injection and blow molding machine first injection molding billet, the hot billet longitudinal stretching, and then through the compressed air to make it transverse stretching, to obtain the same shape as the mold cavity products. This processing method is mainly used to produce PET raw material products, and the mold accuracy and process requirements are very high.