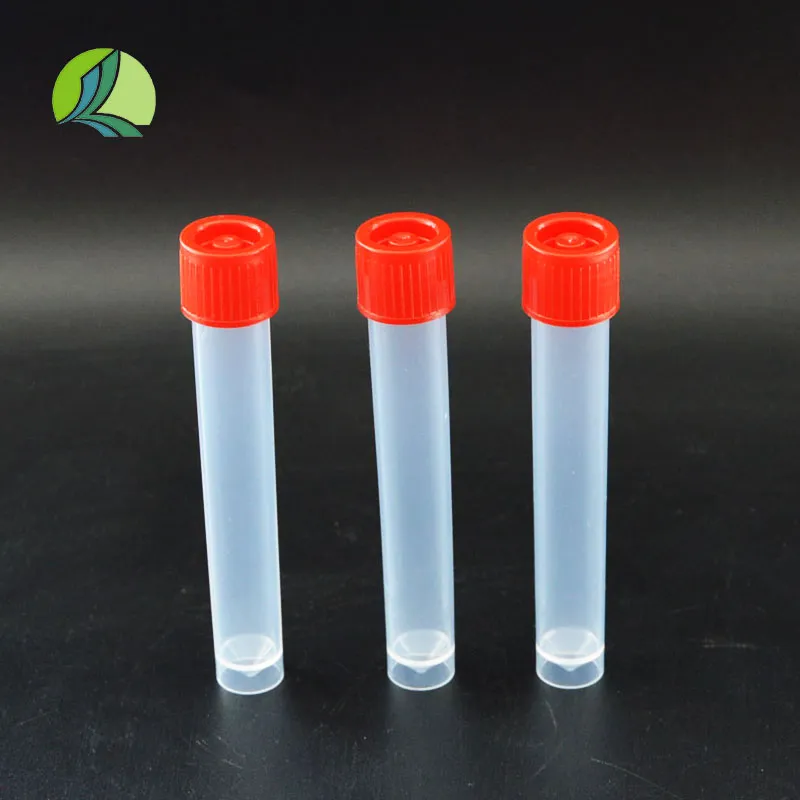

Sterile Virus Sample Tubes: Secure & Reliable Specimen Collection

Innovations in Sample Collection: The Advanced virus sample tube

In the rapidly evolving landscape of medical diagnostics and public health, the integrity and safety of biological samples are paramount. The virus sample tube stands as a critical component in this ecosystem, designed to ensure the stability and viability of viral specimens from collection to laboratory analysis. These specialized sample tube solutions are engineered to meet stringent requirements for sterility, containment, and preservation, playing an indispensable role in disease surveillance, research, and clinical diagnostics. As global health challenges continue to highlight the importance of rapid and reliable testing, the demand for advanced and highly efficient virus sample tube technologies continues to escalate, driving innovation in material science, manufacturing processes, and preservation media. Our focus is on providing solutions that enhance diagnostic accuracy and operational efficiency for healthcare providers, research institutions, and public health agencies worldwide.

Understanding the nuanced requirements of viral diagnostics, our virus sample tube offerings are meticulously designed to safeguard sample quality. These include robust construction from medical-grade polypropylene (PP) or polystyrene (PS), ensuring chemical inertness and resistance to breakage. Each virus sample tube is typically pre-filled with a specific Viral Transport Medium (VTM) or Universal Transport Medium (UTM) formulated to maintain viral viability for extended periods at various temperatures, preventing degradation while inactivating potential pathogens for safe handling. The design prioritizes ease of use for healthcare professionals during sample collection and secure sealing to prevent leakage during transport, adhering to international biohazard safety standards. This holistic approach ensures that from the point of collection, the sample remains stable and representative for subsequent nucleic acid extraction and PCR testing, a cornerstone of modern molecular diagnostics.

The Manufacturing Excellence: Crafting the Optimal Sample Tube

The production of a high-quality virus sample tube is a sophisticated process that demands precision engineering and adherence to rigorous quality control standards. Unlike general purpose test tubes used for basic laboratory experiments, the manufacturing of medical-grade tubes for sample collection, especially for viral transport, involves a series of meticulously controlled steps to ensure sterility, integrity, and performance.

Detailed Manufacturing Process of a Virus Sample Tube:

- Material Selection (Medical-Grade Polymer): The foundational step involves selecting high-purity, medical-grade polypropylene (PP) or polystyrene (PS) resin. These polymers are chosen for their excellent optical clarity, chemical inertness, low protein binding properties, and resistance to breakage, ensuring they do not interfere with the sample or the transport medium. All raw materials comply with USP Class VI standards for biocompatibility.

- Injection Molding (Precision Fabrication): The selected polymer granules are heated and injected into precision molds under high pressure. This process, known as injection molding, creates the virus sample tube body and cap components with exact dimensions and smooth interior surfaces. The molds are designed to prevent retention of liquids and facilitate easy sample retrieval.

- Assembly and Filling (Automated Cleanroom Environment): In an ISO Class 7 or Class 8 cleanroom environment, the molded components are automatically assembled. This typically involves attaching the cap to the tube and then precisely filling each virus sample tube with a predetermined volume of Viral Transport Medium (VTM) or Universal Transport Medium (UTM). These specialized media are formulated with buffered salts, proteins (e.g., BSA), antibiotics, and sometimes cryoprotectants to preserve viral RNA/DNA integrity and inhibit bacterial/fungal contamination without inactivating the virus itself. For some applications, inactivation buffers containing detergents and chaotropic salts are used to rapidly inactivate viruses while stabilizing nucleic acids for safer transport and immediate downstream processing.

- Sterilization (Validated Methodologies): Post-filling and sealing, the virus sample tube units undergo terminal sterilization. Common methods include Gamma Irradiation or Ethylene Oxide (EO) sterilization. Both processes are rigorously validated to achieve a Sterility Assurance Level (SAL) of 10⁻⁶, meaning there is less than one chance in a million of a non-sterile unit. This ensures the tubes are entirely free from viable microorganisms, crucial for preventing sample contamination and ensuring diagnostic accuracy.

- Quality Control and Testing (Comprehensive Standards): Throughout the entire process, multiple quality control checkpoints are implemented. This includes visual inspections for defects, dimensional checks, leak tests (pressure and vacuum), testing for RNase/DNase contamination, endotoxin levels, and sterility testing. Performance validation also includes assessing the stability of the transport medium over time and its efficacy in preserving viral nucleic acids. All manufacturing processes and products adhere to international standards such as ISO 13485 (Medical Devices Quality Management Systems) and often bear CE-IVD marking for European market conformity and FDA clearance for the US market. The typical shelf life for a sealed virus sample tube is 18-24 months from the date of manufacture.

This meticulous manufacturing protocol ensures that each virus sample tube meets the high demands of clinical diagnostics and research, providing a reliable and safe container111 for crucial biological samples. The emphasis on sterile manufacturing and validated quality control means these tubes are suitable for industries such as clinical diagnostics, public health laboratories, pharmaceutical research, and biotechnology where sample integrity is non-negotiable. Their inherent advantages lie in maintaining sample viability, preventing cross-contamination, and ensuring safety for handlers, which is critical for accurate and timely disease detection and management.

Technical Specifications and Parameters of Virus Sample Tubes

The performance of a virus sample tube is defined by its precise technical specifications, which dictate its suitability for various diagnostic applications. These parameters are critical for laboratory professionals assessing the compatibility and reliability of different types of sample collection tubes.

Key Technical Parameters of a Standard Virus Sample Tube:

| Parameter | Typical Specification | Significance for Usage |

|---|---|---|

| Tube Material | Medical-grade Polypropylene (PP) or Polystyrene (PS) | Ensures chemical inertness, high clarity, and resistance to breakage. RNase/DNase-free and non-cytotoxic. |

| Tube Volume Capacity | 2mL, 3mL, 5mL, 10mL | Accommodates various sample volumes required for different diagnostic tests. |

| Transport Medium Type | VTM (Viral Transport Medium) or UTM (Universal Transport Medium), Inactivation Buffer | Preserves viral viability and nucleic acid integrity; some formulations inactivate virus for safer handling. |

| Sterilization Method | Gamma Irradiation or Ethylene Oxide (EO) | Achieves Sterility Assurance Level (SAL) of 10⁻⁶, preventing sample contamination. |

| Cap Type | Screw Cap with O-ring/Gasket or Push-on Cap | Ensures leak-proof seal during transport and prevents evaporation or contamination. |

| Storage Temperature Range | 4°C to 25°C (Ambient); Short-term: -20°C; Long-term: -80°C | Indicates stability for transport and long-term storage of samples. |

| Shelf Life | 18-24 months from manufacturing date | Ensures product integrity and medium efficacy over time. |

| Certifications | ISO 13485, CE-IVD, FDA (as applicable) | Confirms adherence to international quality management and regulatory standards for medical devices. |

These detailed specifications underscore the scientific rigor behind the design and manufacturing of each virus sample tube, ensuring that it performs reliably in crucial diagnostic workflows. The selection of the appropriate sample tube based on these parameters directly impacts the quality of the collected specimen and, consequently, the accuracy of diagnostic results.

Applications and Technical Advantages in Diverse Scenarios

The versatility and reliability of the virus sample tube make it indispensable across a spectrum of applications in public health, clinical diagnostics, and research. Its technical advantages stem from its design to preserve the integrity of sensitive biological materials, making it a cornerstone for effective disease management.

Key Application Scenarios:

- Clinical Diagnostics: Essential for collecting nasopharyngeal, oropharyngeal, or saliva samples for PCR-based detection of respiratory viruses (e.g., SARS-CoV-2, Influenza, RSV). The pre-filled transport medium ensures immediate preservation at the point of collection, critical for maintaining viral RNA stability during transport to centralized testing laboratories.

- Epidemiological Surveillance: Facilitates large-scale collection and transport of samples for tracking disease outbreaks, monitoring viral strains, and assessing vaccine effectiveness. The standardized format of the virus sample tube supports efficient processing in high-throughput testing environments.

- Research and Development: Provides a reliable means for researchers to collect and store viral specimens for studies on viral pathogenesis, drug discovery, and vaccine development. The integrity of the sample, preserved by the transport medium, is crucial for accurate experimental outcomes.

- Public Health Screening Programs: Integral to community-wide testing initiatives, ensuring safe and effective sample collection from diverse populations. The robust design of the virus sample tube minimizes breakage and leakage, enhancing safety for both collectors and laboratory personnel.

Technical Advantages:

- Optimal Sample Preservation: The proprietary VTM/UTM formulations within each virus sample tube are designed to stabilize viral nucleic acids for up to 72 hours at refrigerated temperatures (2-8°C), and indefinitely at -70°C or colder. This extended stability window is vital for mitigating sample degradation during logistical delays, particularly in remote or high-volume collection sites.

- Enhanced Safety Profile: Tubes pre-filled with inactivation buffer rapidly lyse viral particles upon contact, rendering them non-infectious while preserving nucleic acids. This significantly reduces biohazard risks for healthcare workers and laboratory technicians handling the sample tube, streamlining the workflow by eliminating the need for separate inactivation steps in the lab.

- Leak-Proof Design: Equipped with precision-engineered screw caps featuring an O-ring or unique sealing mechanisms, the virus sample tube offers superior leak prevention. This ensures containment of potentially infectious materials, adhering to stringent IATA (International Air Transport Association) packing instructions for Category B biological substances (UN3373) for safe transport.

- High Compatibility: Our virus sample tube products are compatible with a wide array of automated nucleic acid extraction platforms and PCR systems, ensuring seamless integration into existing laboratory workflows. This compatibility reduces manual handling errors and increases throughput, essential for rapid diagnostic turnaround times.

- Traceability and Compliance: Each virus sample tube typically features clear labeling, including lot numbers, expiration dates, and volume indicators. Manufactured under ISO 13485 certified quality management systems and often bearing CE-IVD marks, these tubes meet global regulatory requirements, offering confidence in their performance and traceability.

These technical advantages position the virus sample tube as a superior choice for reliable and safe viral sample collection, crucial for accurate and timely diagnostic outcomes across various medical and research settings.

Manufacturer Comparison and WKPACKING's Unique Value Proposition

The market for virus sample tube solutions is diverse, with several manufacturers offering products that vary in specifications, quality, and overall value. For B2B decision-makers, understanding these differences is crucial for selecting a partner that aligns with specific operational needs and quality standards. WKPACKING distinguishes itself through a commitment to superior product quality, innovative design, and comprehensive customer support.

Comparative Analysis of Virus Sample Tubes:

| Feature/Criterion | Competitor A (General) | Competitor B (Specialized) | WKPACKING Virus Sample Tube |

|---|---|---|---|

| Tube Material Quality | Standard PP | Medical-grade PP | Premium Medical-grade PP (USP Class VI) |

| Transport Medium Stability (at 4°C) | ~48 hours | ~72 hours | Up to 72-96 hours (validated) |

| Leak-Proof Design | Basic screw cap | Screw cap with O-ring | Enhanced Screw Cap with Bi-directional Gasket Seal (IATA compliant) |

| Sterilization Assurance Level (SAL) | 10⁻³ to 10⁻⁵ | 10⁻⁶ | 10⁻⁶ (validated Gamma/EO) |

| Regulatory Compliance | CE | ISO 13485, CE-IVD | ISO 13485, CE-IVD, FDA Cleared (where applicable) |

| Customization Options | Limited (volume only) | Medium (media, label) | Extensive (tube size, cap color, media formulation, labeling, kitting) |

| Customer Support & After-sales | Standard | Good | Dedicated Technical Support, Global Logistics, Warranty |

WKPACKING stands out by offering a virus sample tube that consistently exceeds industry benchmarks in terms of material quality, sample preservation capabilities, and safety features. Our dedication to compliance and robust manufacturing processes, certified under ISO 13485 and possessing relevant market clearances like CE-IVD and FDA, underscores our commitment to providing highly reliable and safe products. We don't just supply tubes for sample collection; we provide comprehensive solutions.

Customized Solutions and Application Cases:

Recognizing that each client may have unique requirements, WKPACKING specializes in offering tailor-made virus sample tube solutions. Our customization capabilities extend to various aspects, including:

- Volume and Format: From micro-collection tubes to larger formats for specific research needs, adapting the size of the virus sample tube to optimize sample collection and storage.

- Media Formulation: Development and filling of custom transport media (VTM, UTM, inactivation buffers) to meet specific viral preservation or inactivation protocols required by research projects or diagnostic assays. This includes adapting media for unique pathogens or analytical methods.

- Kitting Services: Assembling complete sample collection kits that include the virus sample tube, sterile swabs (nasopharyngeal, oropharyngeal, saliva collection devices), patient instructions, and biohazard bags, providing a complete, ready-to-use solution for mass screening or clinical trials.

- Branding and Labeling: Custom printing of client logos, specific barcodes (e.g., 2D matrix, linear barcodes), or unique identifiers directly onto the virus sample tube or its packaging for enhanced traceability and brand integration.

Application Case Example: A large governmental public health agency required a specialized virus sample tube kit for a nationwide infectious disease surveillance program. They needed a high-volume capacity tube pre-filled with an inactivation buffer to ensure immediate viral inactivation at the point of collection, simplifying transport and laboratory handling while enhancing safety. WKPACKING collaborated closely with the agency's scientific team to custom-formulate the inactivation buffer, design a unique ergonomic tube cap, and integrate all components into a sterile, ready-to-deploy collection kit. This solution significantly reduced biohazard risks, streamlined logistics, and improved turnaround times for tens of millions of tests, demonstrating our capability to deliver complex, high-impact solutions. Our track record, spanning over 15 years in providing medical consumables, reinforces our authority and reliability as a partner.

Ensuring Trust: FAQs, Delivery, Warranty, and Support

At WKPACKING, building and maintaining customer trust is fundamental to our operations. We understand that for B2B clients, clarity on product capabilities, logistics, and post-purchase support is as critical as the product itself. Our commitment to trustworthiness is reflected in our transparent policies regarding quality assurance, delivery, and ongoing technical support for every virus sample tube we provide.

Frequently Asked Questions (FAQs):

- Q: What is the optimal storage temperature for the virus sample tube before use?

A: Our virus sample tube products should be stored at ambient temperature (4°C to 25°C) away from direct sunlight. Once a sample is collected, it should be transported and processed according to specific protocol guidelines, typically refrigerated (2-8°C) for short-term transport (up to 72 hours) or frozen at -20°C to -80°C for long-term storage. - Q: Are the tubes compatible with automated processing systems?

A: Yes, our virus sample tube designs are engineered to be compatible with a wide range of automated liquid handling and nucleic acid extraction platforms commonly used in clinical and research laboratories. We can provide specific compatibility documentation upon request. - Q: What certifications do your virus sample tubes hold?

A: All our virus sample tube products are manufactured under an ISO 13485 certified Quality Management System. Depending on the region, they may also carry CE-IVD marking for the European market and relevant FDA clearances for the US market, ensuring compliance with global regulatory standards for in vitro diagnostic medical devices. - Q: Can the transport medium be customized?

A: Absolutely. We offer extensive customization for the transport medium, including variations in volume, components (e.g., adding specific antibiotics, cryoprotectants, or inactivation agents), and pH buffers. Our R&D team can collaborate with you to develop a medium tailored to your specific assay or research requirements for your unique sample tube needs.

Delivery Timelines:

Our streamlined production and logistics ensure efficient delivery of your virus sample tube orders.

- Standard Orders: For standard configurations of the virus sample tube, typical lead times are 2-4 weeks from order confirmation, depending on volume and current production schedules.

- Customized Orders: Custom virus sample tube solutions, including specialized media or kitting, may require 4-8 weeks for initial production and validation, followed by standard delivery times. We provide detailed project timelines upon consultation.

- Urgent Requirements: For critical, time-sensitive projects, expedited production and shipping options are available upon request and feasibility assessment.

Quality Assurance and Warranty:

WKPACKING stands by the quality and performance of every virus sample tube manufactured.

- Product Warranty: We offer a 12-month warranty from the date of purchase against manufacturing defects and non-conformity to stated specifications, provided the virus sample tube products are stored and used as recommended.

- Certificates of Analysis (CoA): Each batch of virus sample tube products is accompanied by a comprehensive Certificate of Analysis (CoA), detailing key quality control parameters such as sterility, pH of the medium, fill volume accuracy, and integrity testing results.

Dedicated Customer Support:

Our commitment extends beyond delivery. WKPACKING provides continuous technical support to ensure optimal utilization of our virus sample tube products. Our team of experienced technical specialists is available to assist with product selection, troubleshoot application issues, and provide guidance on best practices for sample collection and handling. We aim to be a long-term partner in your diagnostic and research endeavors.

References

- World Health Organization (WHO). Laboratory testing for coronavirus disease 2019 (COVID-19) in suspected human cases: interim guidance. WHO/COVID-19/Lab/2020.6, 2020.

- Centers for Disease Control and Prevention (CDC). Interim Guidelines for Collecting, Handling, and Testing Clinical Specimens for COVID-19. Updated regularly.

- International Organization for Standardization (ISO). ISO 13485:2016 Medical devices - Quality management systems - Requirements for regulatory purposes.

- Clinical and Laboratory Standards Institute (CLSI). M40-A2: Viral Culture and Rapid Identification (Approved Guideline). 2nd ed. CLSI, 2011.

-

White 250ml Plastic Vaccine Vial for Lab & Vet MedicineNewsAug.14,2025

-

Premium Clear Plastic Vaccine Vials for Lab & Vet MedicineNewsAug.13,2025

-

Plastic Clear Vaccine Vials | Lab & Vet Liquid StorageNewsAug.12,2025

-

Secure 250ml Blue Plastic Vaccine Vials for Lab & VetNewsAug.11,2025

-

250ml Blue Translucent Plastic Vaccine Vials - Medical GradeNewsAug.10,2025