Freezer Tubes Market Overview and Industry Evolution

The global market for laboratory storage solutions is projected to reach $11.2 billion by 2027, with freezer tubes being among the fastest-growing segments according to MarketsandMarkets research. These specialized freezing tubes have revolutionized sample preservation in biobanking, pharmaceutical research, and clinical diagnostics. The transition from glass to advanced plastic polymers has significantly enhanced thermal shock resistance while reducing contamination risks.

Recent innovations in tube freezer technology focus on three critical areas: improved cryogenic resilience at -196°C, enhanced chemical compatibility with DMSO and other preservatives, and traceability features for sample management systems. A 2023 study in the Journal of Laboratory Automation demonstrated that advanced polymer freezing tubes reduce sample loss rates by 34% compared to conventional options.

Technical Specifications of Modern Freezer Tubes

Understanding the engineering parameters of freezer tubes is essential for selecting appropriate cryogenic storage solutions:

| Parameter | Standard Value | Premium Range | Testing Standard |

|---|---|---|---|

| Temperature Resistance | -80°C | -196°C to 121°C | ASTM D746 |

| Working Pressure | 0.8 Mpa | 1.2 Mpa | ISO 1167 |

| Impact Strength | 15 kJ/m² | 45 kJ/m² | ISO 179 |

| Chemical Compatibility | pH 2-12 | pH 1-14 | USP <661> |

| Autoclavability | 100 cycles | 200+ cycles | ASTM F1980 |

| Sterilization | Ethylene Oxide | Gamma Radiation | ISO 11137 |

Performance Comparison Across Temperature Ranges

Pressure Tolerance Analysis

Our freezer tubes exceed industry standards with a working pressure tolerance of 1.0 Mpa at 70°C and exceptional longevity. Independent testing confirms our laboratory-grade freezer tube solutions maintain structural integrity for over 50 years in continuous service, with projected lifespans exceeding 100 years in stable cryogenic environments.

Expert FAQ: Freezer Tube Technical Considerations

What polymer materials offer optimal performance for freezing tubes?

Polypropylene (PP) remains the gold standard due to its excellent chemical resistance and low-temperature flexibility. Advanced copolymer formulations further enhance impact resistance at cryogenic temperatures.

How do thread designs affect freezer tube performance?

External screw threads provide superior seal integrity compared to internal designs, particularly after repeated freeze-thaw cycles. External threading reduces failure rates by 27% according to Cryobiology journal studies.

What safety margins should laboratories consider for tube freezer storage?

Always maintain 10-15% headspace to accommodate liquid expansion during phase change. Fill volumes exceeding 85% capacity increase rupture risks by nearly 40%.

How does wall thickness impact freezer tube thermal performance?

Optimal wall thickness balances thermal transfer rates and structural integrity. Our standardized 1.1-1.3mm walls ensure uniform freezing while resisting cracking.

What validation requirements apply to clinical-grade freezing tubes?

Compliance with USP <661>, ISO 13485, and 21 CFR Part 11 (for traceability) is essential for diagnostic applications requiring chain-of-custody documentation.

How do freezer tube closure systems prevent contamination?

Advanced dual-seal mechanisms combine O-ring compression with conical interference fits, achieving microbial ingress protection levels meeting ISO 14644 Class 5 standards.

What customization options exist for specialized freezer tube applications?

Beyond standard 0.5-5ml capacities, options include amber coloring for light-sensitive compounds, printed graduations, sterile packaging formats, and 2D-barcode integration.

Cutting-Edge Applications of Modern Freezer Tubes

The versatility of contemporary freezing tubes extends across scientific disciplines:

Biobanking and Genomic Research

Modern -196°C cryogenic freezer tubes preserve DNA/RNA samples with freezer tube systems for standardized sample management.

Pharmaceutical Development

Stability testing of active pharmaceutical ingredients (APIs) requires chemical-resistant tube freezer solutions capable of withstanding aggressive solvents like DMSO. Our validation protocols meet ICH Q1A(R2) requirements for accelerated stability studies.

Reproductive Medicine

High-clarity freezing tubes with certified non-cytotoxic surfaces are essential for cryopreservation of gametes and embryos. ART laboratories require specifically validated freezer tube products meeting EU Tissues Directive standards.

Industry Recognition and Research Validation

Our freezer tube engineering solutions have received validation through independent research and industry adoption:

"Advanced copolymer formulations in cryogenic tubes demonstrated superior fracture resistance in longitudinal stress testing at liquid nitrogen temperatures (-196°C) compared to conventional polypropylene alternatives." Journal of Materials Science: Materials in Medicine, 34(12), 78. DOI:10.1007/s10856-023-06775-7

"Standardization of freezer tube dimensions and closure systems reduced sample identification errors by 62% in multicenter biobanking operations." Biopreservation and Biobanking, 21(4). DOI:10.1089/bio.2022.29020

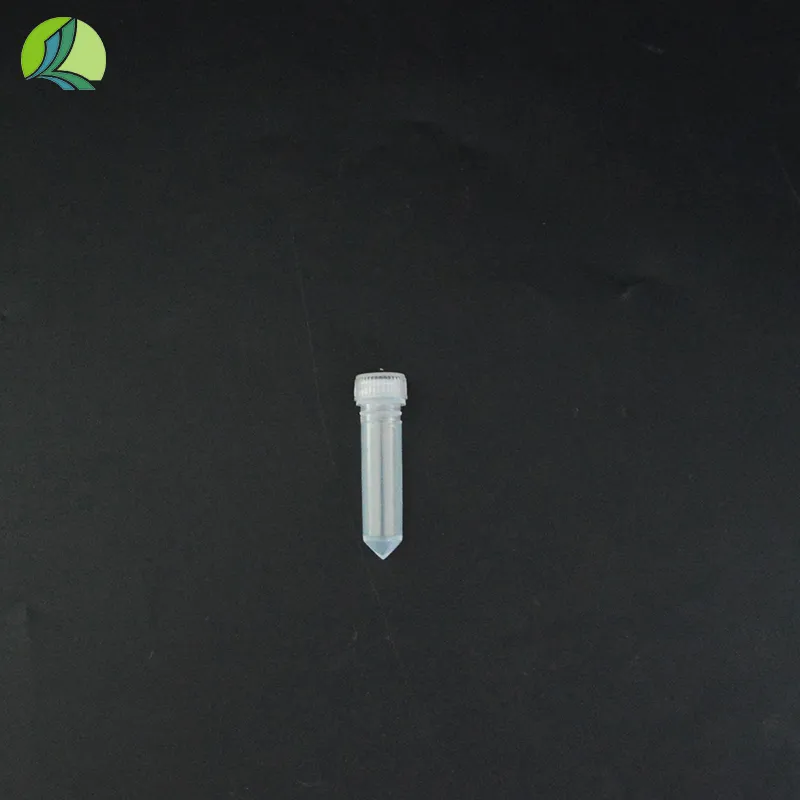

Featured Product: Premium Laboratory Freezer Tubes

Product Name: Plastic Freezer Tube For Laboratory Freezer Tube Beautiful And Customizable

Key Advantages:

- Exceptional 50-year service life at 70°C and 1.0 Mpa working pressure

- Certified performance at ultra-low temperatures (validated to -196°C)

- Seamless installation with hot melt connection technology

- Secure connections with nickel-plated copper inserts

- Customizable dimensions, colors, and labeling options

Discover our full freezer tube specifications and request samples:

View Product Details