Jan . 09, 2025 12:04

Back to list

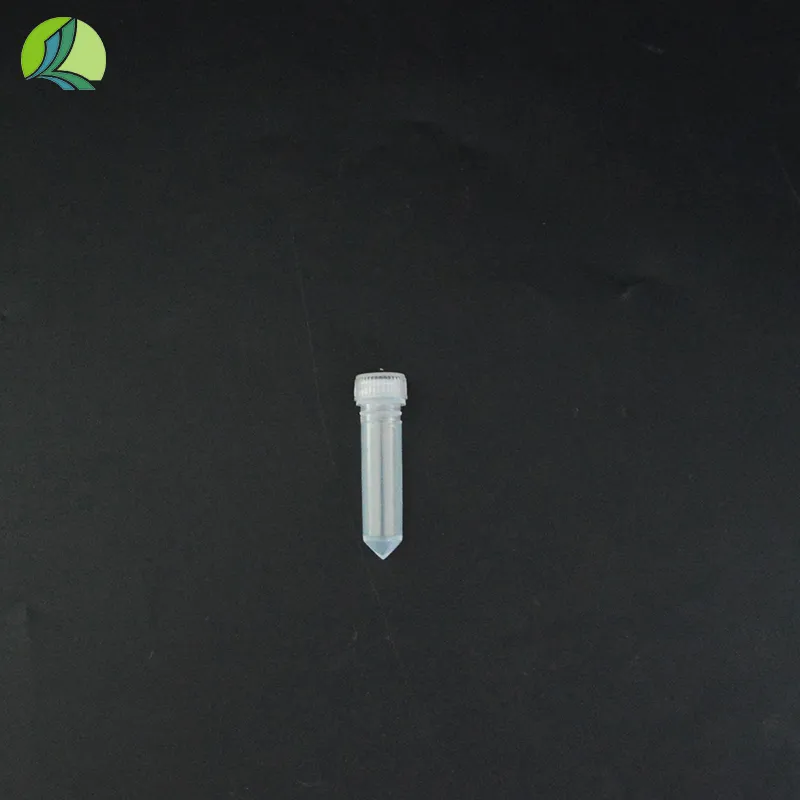

plastic drug vials

Navigating the complex world of pharmaceutical packaging, plastic drug vials have emerged as a pivotal component. Not only do they offer robust storage solutions, but their adaptability and cost-effectiveness make them indispensable for medicine distribution. With advances in technology and stringent requirements for the safety and efficacy of medications, the role of plastic vials has become more significant than ever.

As experts will affirm, the sustainability of packaging materials is increasingly crucial in today's environmentally conscious society. Many firms are now turning to recyclable materials to produce plastic drug vials, aligning with global initiatives to reduce plastic waste. This shift not only underscores a commitment to environmental responsibility but also offers pharmaceutical companies a means to enhance their competitive edge through sustainable practices. In terms of trustworthiness, clear documentation and supplier audits are key when selecting plastic vial providers. Working with certified manufacturers that provide comprehensive data sheets on their materials and manufacturing processes helps to establish the credibility of the product. Ensuring that the production environments are regularly inspected and that the vials meet the rigorous demands of both pharmaceutical and environmental standards confirms their suitability for sensitive medical applications. Plastic drug vials also support advancements in medical technology. For instance, they are often utilized in the field of personalized medicine, where precise dosages need to be contained within small, reliable vessels. The integration of smart technologies, such as embedded RFID chips, further extends their utility, enabling better inventory management and tracking systems in healthcare facilities. In conclusion, the extensive utility of plastic drug vials in modern-day pharmaceutical applications is undisputed. They provide a perfect blend of safety, efficiency, and innovation, which are essential characteristics for any product playing a role in global health. Emphasizing transparency, adherence to regulatory compliances, and a commitment to sustainability will continue to bolster their reputation in a highly regulated industry. As medicine continues to evolve, the adaptability and resilience of plastic drug vials assure that they will remain a staple in pharmaceutical packaging, trusted by professionals worldwide.

As experts will affirm, the sustainability of packaging materials is increasingly crucial in today's environmentally conscious society. Many firms are now turning to recyclable materials to produce plastic drug vials, aligning with global initiatives to reduce plastic waste. This shift not only underscores a commitment to environmental responsibility but also offers pharmaceutical companies a means to enhance their competitive edge through sustainable practices. In terms of trustworthiness, clear documentation and supplier audits are key when selecting plastic vial providers. Working with certified manufacturers that provide comprehensive data sheets on their materials and manufacturing processes helps to establish the credibility of the product. Ensuring that the production environments are regularly inspected and that the vials meet the rigorous demands of both pharmaceutical and environmental standards confirms their suitability for sensitive medical applications. Plastic drug vials also support advancements in medical technology. For instance, they are often utilized in the field of personalized medicine, where precise dosages need to be contained within small, reliable vessels. The integration of smart technologies, such as embedded RFID chips, further extends their utility, enabling better inventory management and tracking systems in healthcare facilities. In conclusion, the extensive utility of plastic drug vials in modern-day pharmaceutical applications is undisputed. They provide a perfect blend of safety, efficiency, and innovation, which are essential characteristics for any product playing a role in global health. Emphasizing transparency, adherence to regulatory compliances, and a commitment to sustainability will continue to bolster their reputation in a highly regulated industry. As medicine continues to evolve, the adaptability and resilience of plastic drug vials assure that they will remain a staple in pharmaceutical packaging, trusted by professionals worldwide.

Share

Prev:

Next:

Latest news

-

Aesthetic Makeup Spray Bottles | Fine Mist Empty RefillableNewsAug.19,2025

-

White Plastic Veterinary Vaccine Vials | Lab Liquid BottlesNewsAug.18,2025

-

Plastic Medicine Liquid Bottle: Secure Flip Top Drug VialsNewsAug.17,2025

-

Durable 250ml Blue Plastic Vaccine Vial for Lab & Vet UseNewsAug.16,2025

-

Sterile Virus Sample Tubes: Secure & Reliable Specimen CollectionNewsAug.15,2025

-

White 250ml Plastic Vaccine Vial for Lab & Vet MedicineNewsAug.14,2025

RECOMMEND PRODUCTS