Jan . 09, 2025 13:52

Back to list

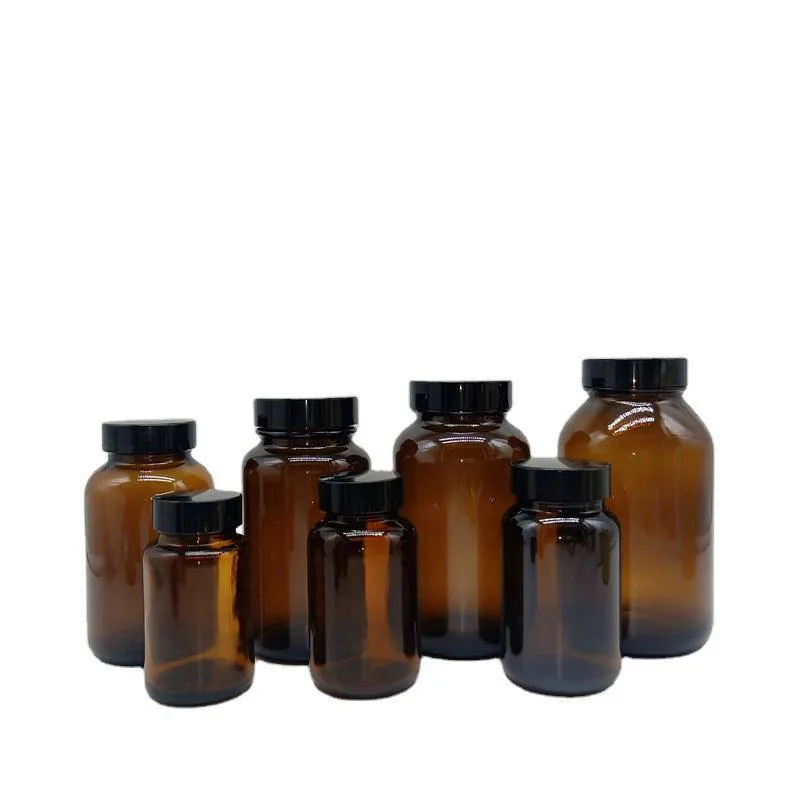

Sterile Vaccine Vial Plastic Liquid Vial For Medical Purposes

The use of plastic drug vials in the pharmaceutical industry has been transformative, offering an ideal solution to a longstanding challenge—ensuring the safety and integrity of medications while enhancing patient experience. As one of the cornerstones of contemporary healthcare packaging, plastic drug vials exemplify the balance between practicality and innovation. This article explores their unique advantages, rooted in real-life applications and expert insights, to establish their authority in the marketplace and build trust among consumers and manufacturers alike.

The transportability of plastic drug vials further underscores their suitability in modern logistics. Lightweight yet sturdy, they significantly reduce shipping costs while minimizing the carbon footprint associated with heavier packaging alternatives. This aspect is crucial as the pharmaceutical industry seeks more sustainable practices. Environmental experts have pointed out that the shift towards plastic vials not only benefits the bottom line but also aligns with global sustainability goals, fostering confidence in the industry’s commitment to environmental stewardship. Trustworthiness is paramount in healthcare, and the pharmaceutical industry is no exception. The integrity of plastic drug vials has been verified through rigorous testing and scientific validation. Numerous studies confirm their efficacy in protecting medication integrity, establishing these vials as a trusted option among healthcare professionals. Patients, too, can rest assured knowing that their medication is safeguarded by packaging that meets the highest standards of quality and safety. Ultimately, the expert consensus around plastic drug vials underscores their indispensability in pharmaceutical packaging. Their development is a testament to the collaboration between materials scientists, packaging engineers, and healthcare professionals—all working towards a common goal of improving patient outcomes. Manufacturers continue to innovate, striving for improvements that further enhance the functionality and reliability of these vials. In conclusion, plastic drug vials stand at the forefront of pharmaceutical packaging solutions, representing a blend of resilience, adaptability, and trustworthiness. Their widespread use and endorsement by professionals attest to their critical role in maintaining medication safety and patient well-being. As the healthcare landscape continues to evolve, these vials will remain a pivotal element in ensuring that medication reaches patients in its intended form, thus validating their top-tier status within the industry.

The transportability of plastic drug vials further underscores their suitability in modern logistics. Lightweight yet sturdy, they significantly reduce shipping costs while minimizing the carbon footprint associated with heavier packaging alternatives. This aspect is crucial as the pharmaceutical industry seeks more sustainable practices. Environmental experts have pointed out that the shift towards plastic vials not only benefits the bottom line but also aligns with global sustainability goals, fostering confidence in the industry’s commitment to environmental stewardship. Trustworthiness is paramount in healthcare, and the pharmaceutical industry is no exception. The integrity of plastic drug vials has been verified through rigorous testing and scientific validation. Numerous studies confirm their efficacy in protecting medication integrity, establishing these vials as a trusted option among healthcare professionals. Patients, too, can rest assured knowing that their medication is safeguarded by packaging that meets the highest standards of quality and safety. Ultimately, the expert consensus around plastic drug vials underscores their indispensability in pharmaceutical packaging. Their development is a testament to the collaboration between materials scientists, packaging engineers, and healthcare professionals—all working towards a common goal of improving patient outcomes. Manufacturers continue to innovate, striving for improvements that further enhance the functionality and reliability of these vials. In conclusion, plastic drug vials stand at the forefront of pharmaceutical packaging solutions, representing a blend of resilience, adaptability, and trustworthiness. Their widespread use and endorsement by professionals attest to their critical role in maintaining medication safety and patient well-being. As the healthcare landscape continues to evolve, these vials will remain a pivotal element in ensuring that medication reaches patients in its intended form, thus validating their top-tier status within the industry.

Share

Latest news

-

Aesthetic Makeup Spray Bottles | Fine Mist Empty RefillableNewsAug.19,2025

-

White Plastic Veterinary Vaccine Vials | Lab Liquid BottlesNewsAug.18,2025

-

Plastic Medicine Liquid Bottle: Secure Flip Top Drug VialsNewsAug.17,2025

-

Durable 250ml Blue Plastic Vaccine Vial for Lab & Vet UseNewsAug.16,2025

-

Sterile Virus Sample Tubes: Secure & Reliable Specimen CollectionNewsAug.15,2025

-

White 250ml Plastic Vaccine Vial for Lab & Vet MedicineNewsAug.14,2025

RECOMMEND PRODUCTS