Jan . 11, 2025 10:21

Back to list

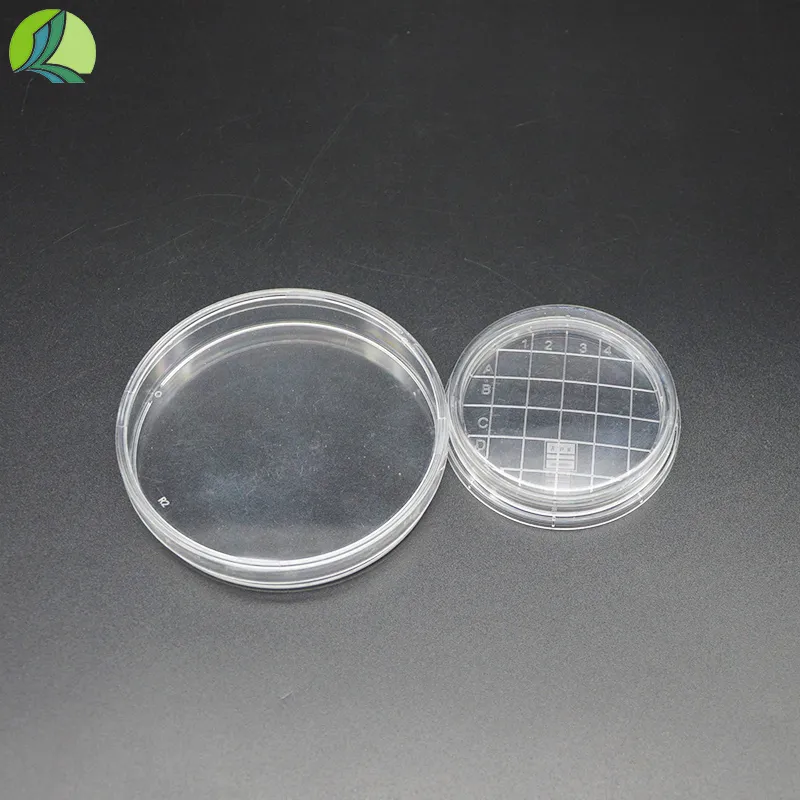

plastic drug vials

Plastic vials with caps are an essential component in industries ranging from pharmaceuticals to cosmetics, and even in laboratories. Their importance lies largely in their ability to securely contain a wide array of substances without risking contamination. In the competitive landscape of products that utilize such vials, understanding their construction, benefits, and applications is vital for selecting the right option for your needs.

The versatility of plastic vials with caps extends to their customization options. For businesses looking to establish a strong brand presence, these vials can be tailored with specific colors, logos, or labeling. This capacity for personalization not only helps in branding efforts but also aids in regulatory compliance by allowing for the inclusion of necessary information directly on the vial. Such customization supports both practicality and marketing, making these vials an asset to any business's product line. When it comes to trustworthiness, it’s important to source plastic vials from reputable suppliers who provide transparency regarding the materials used and the certifications they hold. For those in the pharmaceutical or food industries, it is crucial to ensure that the vials are food-grade and comply with FDA or equivalent international standards. Engaging with suppliers who can offer detailed documentation and traceability of their products adds an extra layer of assurance. Choosing the right plastic vial comes down to understanding your specific needs and the nature of your industry. For laboratory environments, where sample purity and safety are paramount, opt for vials with tamper-evident caps and those that can withstand autoclaving or other sterilization methods. For commercial use, consider the presentation and ease of use, such as vials with user-friendly dispensing caps. In conclusion, plastic vials with caps are more than mere containers; they are complex instruments that play a vital role in protecting and preserving their contents. Their adaptability, robust construction, and potential for customization make them indispensable in numerous sectors. By aligning with suppliers who demonstrate expertise and a commitment to quality, businesses can leverage these vials to enhance their operational efficiency and brand reputation. Understanding the full spectrum of their capabilities and applications ensures that these vials are utilized to their maximum potential.

The versatility of plastic vials with caps extends to their customization options. For businesses looking to establish a strong brand presence, these vials can be tailored with specific colors, logos, or labeling. This capacity for personalization not only helps in branding efforts but also aids in regulatory compliance by allowing for the inclusion of necessary information directly on the vial. Such customization supports both practicality and marketing, making these vials an asset to any business's product line. When it comes to trustworthiness, it’s important to source plastic vials from reputable suppliers who provide transparency regarding the materials used and the certifications they hold. For those in the pharmaceutical or food industries, it is crucial to ensure that the vials are food-grade and comply with FDA or equivalent international standards. Engaging with suppliers who can offer detailed documentation and traceability of their products adds an extra layer of assurance. Choosing the right plastic vial comes down to understanding your specific needs and the nature of your industry. For laboratory environments, where sample purity and safety are paramount, opt for vials with tamper-evident caps and those that can withstand autoclaving or other sterilization methods. For commercial use, consider the presentation and ease of use, such as vials with user-friendly dispensing caps. In conclusion, plastic vials with caps are more than mere containers; they are complex instruments that play a vital role in protecting and preserving their contents. Their adaptability, robust construction, and potential for customization make them indispensable in numerous sectors. By aligning with suppliers who demonstrate expertise and a commitment to quality, businesses can leverage these vials to enhance their operational efficiency and brand reputation. Understanding the full spectrum of their capabilities and applications ensures that these vials are utilized to their maximum potential.

Share

Prev:

Next:

Latest news

-

Aesthetic Makeup Spray Bottles | Fine Mist Empty RefillableNewsAug.19,2025

-

White Plastic Veterinary Vaccine Vials | Lab Liquid BottlesNewsAug.18,2025

-

Plastic Medicine Liquid Bottle: Secure Flip Top Drug VialsNewsAug.17,2025

-

Durable 250ml Blue Plastic Vaccine Vial for Lab & Vet UseNewsAug.16,2025

-

Sterile Virus Sample Tubes: Secure & Reliable Specimen CollectionNewsAug.15,2025

-

White 250ml Plastic Vaccine Vial for Lab & Vet MedicineNewsAug.14,2025

RECOMMEND PRODUCTS