-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 30, 2025 03:52

Back to list

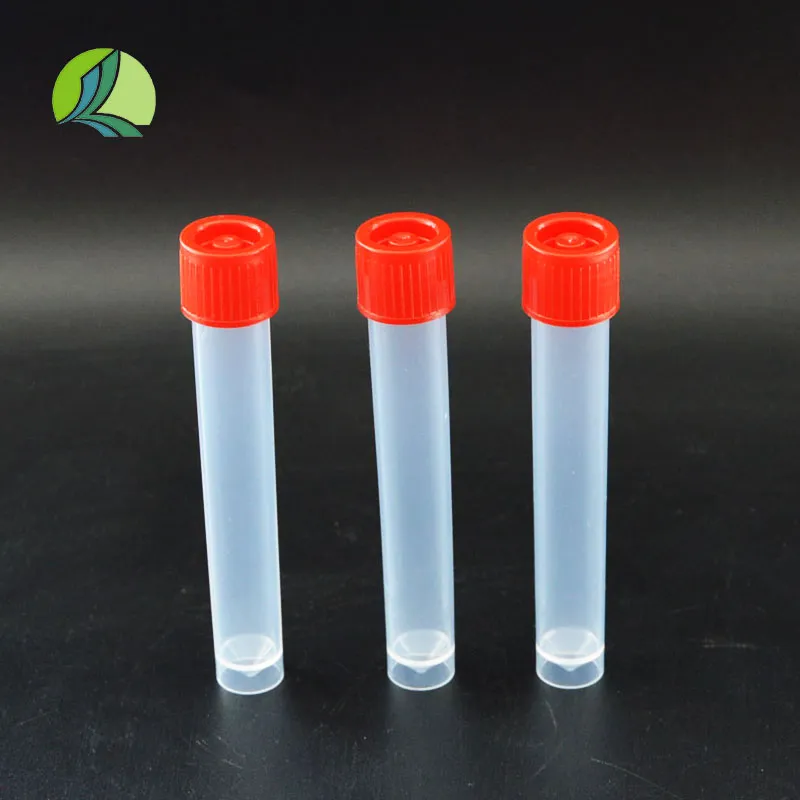

plastic reagent bottle factory

Plastic reagent bottles have become an essential tool in various scientific fields, providing a reliable and safe method of storing chemical substances. Selecting an appropriate material for these bottles is critical, as it directly influences their performance and safety. In this article, we will delve into the different materials used for plastic reagent bottles, focusing on their characteristics and suitability for specific applications, bolstering our understanding with practical experience and expert insights.

Polyvinyl chloride (PVC) is occasionally used for reagent bottles, particularly where flexibility is a priority. While PVC offers decent chemical resistance and is budget-friendly, it is less resilient when exposed to high temperatures and some organic solvents. Practical applications of PVC bottles are mainly focused on short-term storage or non-critical situations, where budget constraints may necessitate their use over more robust materials. Personal experience within the field underscores the importance of understanding the chemical compatibility of these materials with the reagents they are intended to store. For instance, failure to match a chemical reagent with a compatible plastic can lead to degradation of the bottle or even hazardous leaks. Experts advise conducting thorough compatibility testing as a routine part of laboratory safety protocols. Authoritative voices in the scientific community stress the significance of regulatory compliance in selecting materials for reagent bottles. Standards such as those stipulated by the ASTM or ISO ensure that the bottles meet safety and quality benchmarks, thereby fostering trust in their use. Researchers should prioritize products that carry such certifications, as they are indicative of a commitment to safety and reliability. In conclusion, the selection of plastic reagent bottle material is a decision that hinges on various factors including chemical compatibility, temperature tolerance, cost, and regulatory adherence. By leveraging insights from real-world experiences and authoritative sources, one can navigate these choices more effectively, ensuring safety, efficacy, and trustworthiness in laboratory practice. Stay informed and make educated decisions that reflect both expertise and a commitment to scientific excellence.

Polyvinyl chloride (PVC) is occasionally used for reagent bottles, particularly where flexibility is a priority. While PVC offers decent chemical resistance and is budget-friendly, it is less resilient when exposed to high temperatures and some organic solvents. Practical applications of PVC bottles are mainly focused on short-term storage or non-critical situations, where budget constraints may necessitate their use over more robust materials. Personal experience within the field underscores the importance of understanding the chemical compatibility of these materials with the reagents they are intended to store. For instance, failure to match a chemical reagent with a compatible plastic can lead to degradation of the bottle or even hazardous leaks. Experts advise conducting thorough compatibility testing as a routine part of laboratory safety protocols. Authoritative voices in the scientific community stress the significance of regulatory compliance in selecting materials for reagent bottles. Standards such as those stipulated by the ASTM or ISO ensure that the bottles meet safety and quality benchmarks, thereby fostering trust in their use. Researchers should prioritize products that carry such certifications, as they are indicative of a commitment to safety and reliability. In conclusion, the selection of plastic reagent bottle material is a decision that hinges on various factors including chemical compatibility, temperature tolerance, cost, and regulatory adherence. By leveraging insights from real-world experiences and authoritative sources, one can navigate these choices more effectively, ensuring safety, efficacy, and trustworthiness in laboratory practice. Stay informed and make educated decisions that reflect both expertise and a commitment to scientific excellence.

Share

Latest news

-

PTFE Centrifuge Tubes - Chemical Resistant, Leak-proof, Ideal for Laboratory UseNewsJul.05,2025

-

Premium Metal Dropper Bottle for Precise Dispensing 250ml & 1ml Options AvailableNewsJul.04,2025

-

20 ml Headspace Vials - High Quality Polyethylene & Plastic Vials for Lab UseNewsJul.04,2025

-

Small Bottle with Pipette - Precise Dispensing 100ml Pipette Bottles for Essential Oils & Lab UseNewsJun.24,2025

-

Acetic Anhydride Bottle for Accurate Dropper Measurement in Pharmacy Use High-Quality Dropper BottlesNewsJun.10,2025

-

Innovative PET Bottle Design for Juice – Unique Shapes & Customization OptionsNewsJun.10,2025

RECOMMEND PRODUCTS