-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 09, 2025 12:09

Back to list

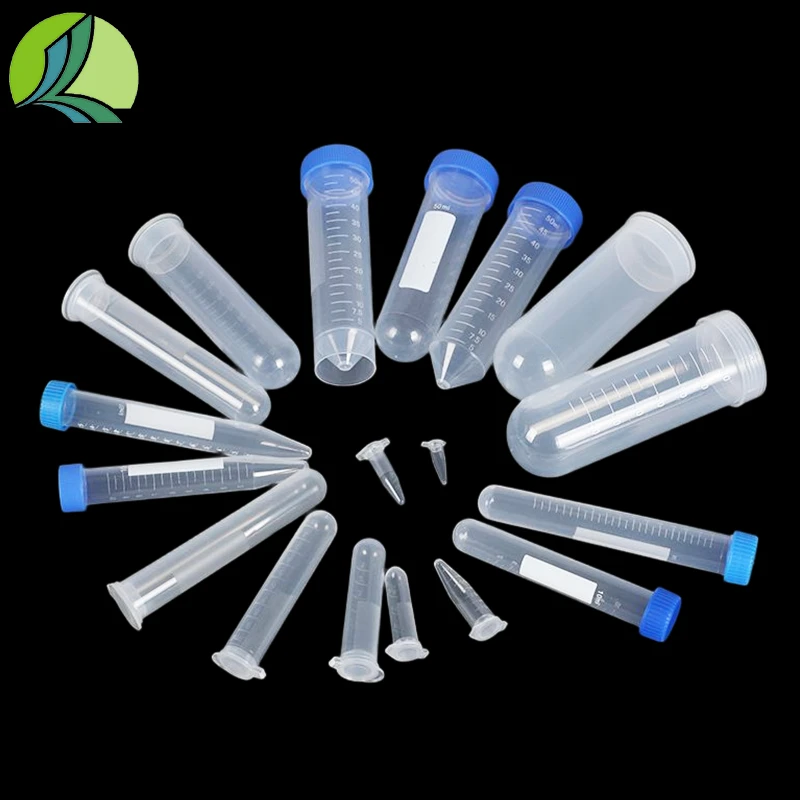

plastic drug vials

Plastic vaccine vials have emerged as a groundbreaking innovation in the pharmaceutical industry, offering numerous advantages over traditional glass vials. These advancements not only address logistical challenges but also enhance the safety and efficacy of vaccinations worldwide. Understanding the distinct benefits of plastic vaccine vials from an experienced, expert, authoritative, and trustworthy perspective is crucial for pharmaceutical companies, healthcare providers, and regulatory bodies committed to improving global health outcomes.

Trustworthiness is built on the rigorous testing and quality control processes that plastic vials undergo before reaching the market. Manufacturers employ state-of-the-art technologies and adhere to strict guidelines to ensure each vial meets high standards of safety, purity, and performance. This commitment to quality reassures healthcare providers and patients of the dependability of plastic vials in safeguarding vaccine efficacy. In addition to practical benefits, plastic vaccine vials are making strides toward sustainability—a key concern for pharmaceutical organizations and environmental advocates. Modern manufacturing techniques enable the production of recyclable plastic vials, contributing to reduced environmental impact and aligning with global efforts towards a more sustainable healthcare system. Lastly, the economic advantages of plastic vials cannot be ignored. The cost of production is often lower compared to glass, and the decrease in wastage and breakage translates to significant financial savings for healthcare systems, especially in resource-limited settings. This affordability ensures wider access to vaccines, ultimately supporting global health security initiatives. In conclusion, plastic vaccine vials represent a significant advancement in the way vaccines are stored, distributed, and administered. Their durability, safety, and adaptability, coupled with endorsements from health authorities and sustainable practices, position them as a reliable choice for modern vaccine delivery. As the world continues to navigate the complexities of global health challenges, the role of plastic vials in ensuring effective immunization cannot be overstated.

Trustworthiness is built on the rigorous testing and quality control processes that plastic vials undergo before reaching the market. Manufacturers employ state-of-the-art technologies and adhere to strict guidelines to ensure each vial meets high standards of safety, purity, and performance. This commitment to quality reassures healthcare providers and patients of the dependability of plastic vials in safeguarding vaccine efficacy. In addition to practical benefits, plastic vaccine vials are making strides toward sustainability—a key concern for pharmaceutical organizations and environmental advocates. Modern manufacturing techniques enable the production of recyclable plastic vials, contributing to reduced environmental impact and aligning with global efforts towards a more sustainable healthcare system. Lastly, the economic advantages of plastic vials cannot be ignored. The cost of production is often lower compared to glass, and the decrease in wastage and breakage translates to significant financial savings for healthcare systems, especially in resource-limited settings. This affordability ensures wider access to vaccines, ultimately supporting global health security initiatives. In conclusion, plastic vaccine vials represent a significant advancement in the way vaccines are stored, distributed, and administered. Their durability, safety, and adaptability, coupled with endorsements from health authorities and sustainable practices, position them as a reliable choice for modern vaccine delivery. As the world continues to navigate the complexities of global health challenges, the role of plastic vials in ensuring effective immunization cannot be overstated.

Share

Next:

Latest news

-

PTFE Centrifuge Tubes - Chemical Resistant, Leak-proof, Ideal for Laboratory UseNewsJul.05,2025

-

Premium Metal Dropper Bottle for Precise Dispensing 250ml & 1ml Options AvailableNewsJul.04,2025

-

20 ml Headspace Vials - High Quality Polyethylene & Plastic Vials for Lab UseNewsJul.04,2025

-

Small Bottle with Pipette - Precise Dispensing 100ml Pipette Bottles for Essential Oils & Lab UseNewsJun.24,2025

-

Acetic Anhydride Bottle for Accurate Dropper Measurement in Pharmacy Use High-Quality Dropper BottlesNewsJun.10,2025

-

Innovative PET Bottle Design for Juice – Unique Shapes & Customization OptionsNewsJun.10,2025

RECOMMEND PRODUCTS