Jan . 28, 2025 05:00

Back to list

Pharmaceutical 10ml 20ml Brown Pet Plastic Liquid Syrup Bottle With Screw Cap Screen Printing For Medicine Packaging

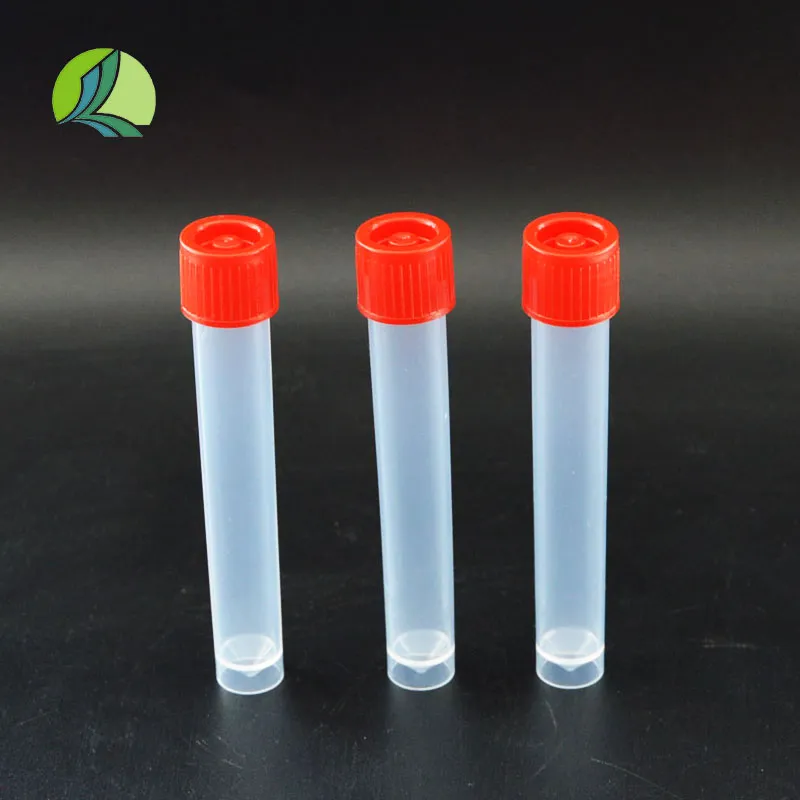

In laboratories worldwide, the reagent bottle stands as an indispensable vessel, fundamentally significant for scientists, researchers, and laboratory technicians. Its pertinence cannot be underestimated due to its essential role in storing, sampling, and handling various chemicals with precision and safety.

Since the usage scenarios of reagent bottles differ significantly across industries—ranging from pharmaceuticals to academia—the customization availability is invaluable. Manufacturers offer a variety of sizes, shapes, and closure types to cater to specific needs, enabling laboratories to select the most appropriate containers based on the volume of reagents required and the nature of the experiments conducted. Moreover, innovation in the production of reagent bottles continues to evolve with advancements in scientific research and experimental requirements. Recent developments have introduced features like UV protection, enabling safe storage of light-sensitive chemicals, and anti-static finishes to reduce the risk of igniting flammable substances. These enhancements contribute to the growing trustworthiness and expertise manufacturers instill in their products, reinforcing their indispensable role within the scientific community. To ensure optimal use and longevity of reagent bottles, laboratories implement effective maintenance routines. Proper cleaning techniques prevent cross-contamination and extend the lifespan of these bottles, maintaining their function and reliability for repeated use. Laboratories often establish protocols detailing the cleaning agents and methods suited for different materials and chemicals to ensure compliance with safety standards. Engaging with professionals familiar with laboratory practices and reagent handling further embodies the essence of expertise and trustworthiness in the realm of reagent bottles. In this context, manufacturers provide comprehensive guides and training resources to facilitate proper usage, handling, and maintenance, empowering laboratory personnel with the knowledge to maximize the utility of these essential vessels. In summary, reagent bottles form the backbone of laboratory apparatus, embodying attributes of safety, versatility, and dependability. Their significance in safely containing and preserving chemical reagents bolsters their established authority and trust within scientific research environments. As laboratories advance and evolve, the continuous innovation and adherence to rigorous safety standards ensure that reagent bottles remain effective, contributing significantly to the accuracy and success of scientific endeavors.

Since the usage scenarios of reagent bottles differ significantly across industries—ranging from pharmaceuticals to academia—the customization availability is invaluable. Manufacturers offer a variety of sizes, shapes, and closure types to cater to specific needs, enabling laboratories to select the most appropriate containers based on the volume of reagents required and the nature of the experiments conducted. Moreover, innovation in the production of reagent bottles continues to evolve with advancements in scientific research and experimental requirements. Recent developments have introduced features like UV protection, enabling safe storage of light-sensitive chemicals, and anti-static finishes to reduce the risk of igniting flammable substances. These enhancements contribute to the growing trustworthiness and expertise manufacturers instill in their products, reinforcing their indispensable role within the scientific community. To ensure optimal use and longevity of reagent bottles, laboratories implement effective maintenance routines. Proper cleaning techniques prevent cross-contamination and extend the lifespan of these bottles, maintaining their function and reliability for repeated use. Laboratories often establish protocols detailing the cleaning agents and methods suited for different materials and chemicals to ensure compliance with safety standards. Engaging with professionals familiar with laboratory practices and reagent handling further embodies the essence of expertise and trustworthiness in the realm of reagent bottles. In this context, manufacturers provide comprehensive guides and training resources to facilitate proper usage, handling, and maintenance, empowering laboratory personnel with the knowledge to maximize the utility of these essential vessels. In summary, reagent bottles form the backbone of laboratory apparatus, embodying attributes of safety, versatility, and dependability. Their significance in safely containing and preserving chemical reagents bolsters their established authority and trust within scientific research environments. As laboratories advance and evolve, the continuous innovation and adherence to rigorous safety standards ensure that reagent bottles remain effective, contributing significantly to the accuracy and success of scientific endeavors.

Share

Latest news

-

Aesthetic Makeup Spray Bottles | Fine Mist Empty RefillableNewsAug.19,2025

-

White Plastic Veterinary Vaccine Vials | Lab Liquid BottlesNewsAug.18,2025

-

Plastic Medicine Liquid Bottle: Secure Flip Top Drug VialsNewsAug.17,2025

-

Durable 250ml Blue Plastic Vaccine Vial for Lab & Vet UseNewsAug.16,2025

-

Sterile Virus Sample Tubes: Secure & Reliable Specimen CollectionNewsAug.15,2025

-

White 250ml Plastic Vaccine Vial for Lab & Vet MedicineNewsAug.14,2025

RECOMMEND PRODUCTS