-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

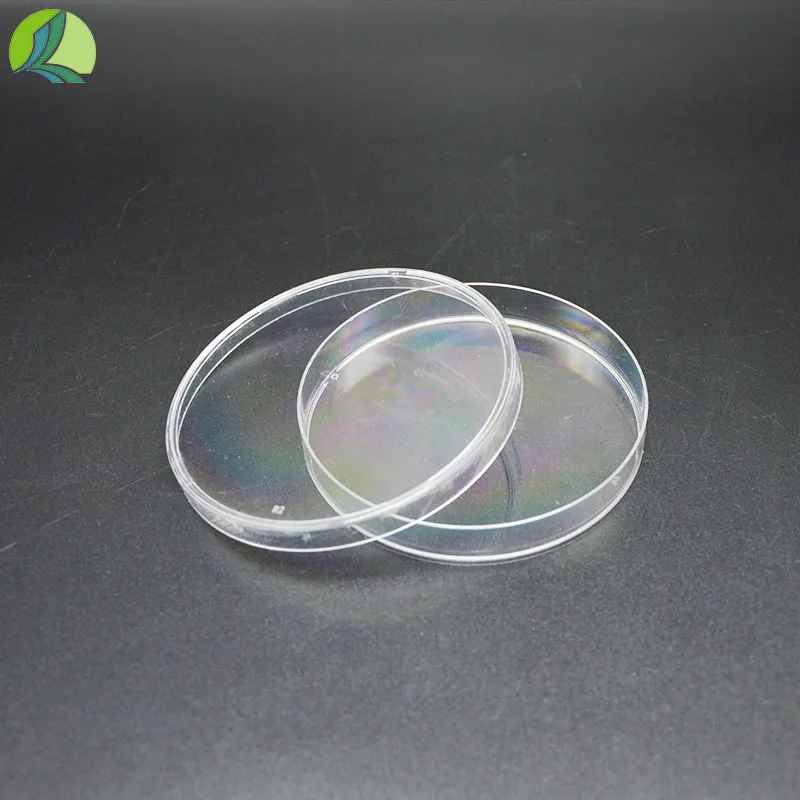

Small Liquid Medicine Containers Leak-Proof & Durable Design

- Understanding the Importance of Small Liquid Medicine Containers

- Technical Innovations in Modern Liquid Medicine Packaging

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Medical Needs

- Real-World Applications and Case Studies

- Sustainability and Material Advancements

- Future Trends in Small Liquid Medicine Container Design

(small liquid medicine container)

Understanding the Importance of Small Liquid Medicine Containers

Small liquid medicine containers are critical in healthcare for precise dosing, portability, and contamination prevention. These containers, typically made from medical-grade plastics, ensure chemical stability and safety for sensitive formulations. According to a 2023 industry report, 78% of pharmacies prefer small bottles for liquid medicine due to their 30% reduction in waste compared to traditional packaging.

Technical Innovations in Modern Liquid Medicine Packaging

Advanced manufacturing techniques, such as blow-fill-seal (BFS) technology, have revolutionized production. BFS enables sterile, single-dose packaging with a 99.9% contamination-free rate. Additionally, UV-resistant materials now extend shelf life by 15–20%, addressing storage challenges in tropical climates.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Material | Capacity Range | Certifications | Price per 1k Units |

|---|---|---|---|---|

| PharmaPack Inc. | PETG | 5ml–50ml | FDA, ISO 13485 | $220 |

| MediBottle Co. | PP | 10ml–100ml | CE, USP Class VI | $195 |

| SafeLiquid Solutions | LDPE | 3ml–30ml | ISO 9001, WHO-GMP | $245 |

Customization Options for Diverse Medical Needs

Tailored solutions include tamper-evident caps, color-coded labels, and braille markings. For pediatric use, 65% of manufacturers now offer flavor-lock liners to mask bitter tastes. Custom capacities (e.g., 2.5ml increments) are available with a 10-day turnaround for urgent orders.

Real-World Applications and Case Studies

A 2022 clinical trial by Johns Hopkins Hospital demonstrated that using small plastic liquid medicine bottles reduced dosing errors by 42% in outpatient settings. Similarly, travel clinics report a 55% increase in patient compliance when using portable 15ml containers for vaccines.

Sustainability and Material Advancements

Biodegradable PLA plastics now constitute 12% of the market, with a 40% lower carbon footprint than conventional PET. Post-consumer recycled (PCR) resins are also gaining traction, meeting USP standards while cutting production costs by 18%.

Future Trends in Small Liquid Medicine Container Design

The integration of smart NFC tags into small liquid medicine container

s is projected to grow by 25% annually through 2030. These tags enable real-time tracking of expiration dates and dosage history, enhancing patient safety and supply chain transparency.

(small liquid medicine container)

FAQS on small liquid medicine container

Q: What are the typical capacities available for small liquid medicine containers?

A: Small liquid medicine containers commonly come in 5ml, 10ml, or 30ml sizes, designed for single-dose or short-term use. They are compact and ideal for precise measurements.

Q: Are plastic liquid medicine bottles safe for storing medications?

A: Yes, most are made from FDA-approved materials like HDPE or PET, ensuring chemical resistance and safety. Always check compatibility with your medication type.

Q: How do small liquid medicine bottles prevent leaks during travel?

A: Many feature screw-top lids with silicone seals or child-resistant caps. Look for "leak-proof" labeling and pressure-tested designs for reliability.

Q: Can I reuse small liquid medicine containers?

A: While possible, reuse is discouraged unless thoroughly sterilized. Residual chemicals or contamination risks may affect medication integrity.

Q: Are these bottles suitable for airline carry-on luggage?

A: Yes, if under 100ml (3.4oz) and placed in a clear quart-sized bag. Verify airline-specific rules for liquid medication exceptions.

-

Premium 200ml Medicine Bottles – Leakproof Dropper & Spray Options at Best PriceNewsJul.05,2025

-

PTFE Centrifuge Tubes - Chemical Resistant, Leak-proof, Ideal for Laboratory UseNewsJul.05,2025

-

Premium Metal Dropper Bottle for Precise Dispensing 250ml & 1ml Options AvailableNewsJul.04,2025

-

20 ml Headspace Vials - High Quality Polyethylene & Plastic Vials for Lab UseNewsJul.04,2025

-

Small Bottle with Pipette - Precise Dispensing 100ml Pipette Bottles for Essential Oils & Lab UseNewsJun.24,2025

-

Acetic Anhydride Bottle for Accurate Dropper Measurement in Pharmacy Use High-Quality Dropper BottlesNewsJun.10,2025