-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

A Tool for Precise Control: Design and Application of Plastic Dropper Bottle

Plastic Dropper Bottle, As the name suggests, it is a container specifically designed for precise control of the distribution of small amounts of liquid. Its structure may seem simple, but it contains intricate design concepts, making it play an irreplaceable role in fields such as scientific research, healthcare, and fine chemicals. Understanding the design principles and advantages of plastic eye dropper bottle helps us gain a deeper understanding of the advancements in modern liquid processing technology.

Plastic Dropper Bottle usually consists of three parts: the bottle body, dropper, and glue head

The body of a small dropper bottles plastic is usually made of transparent or semi transparent plastic material, such as polyethylene (PE) or polypropylene (PP), in order to observe the remaining amount and state of the internal liquid. The selection of plastic materials not only considers cost-effectiveness, but more importantly, their good chemical inertness can ensure that there will be no chemical reaction with the liquid inside the bottle, thereby avoiding pollution or affecting the quality of the liquid.

The dropper of Plastic Dropper Bottle is the core component for achieving precise distribution

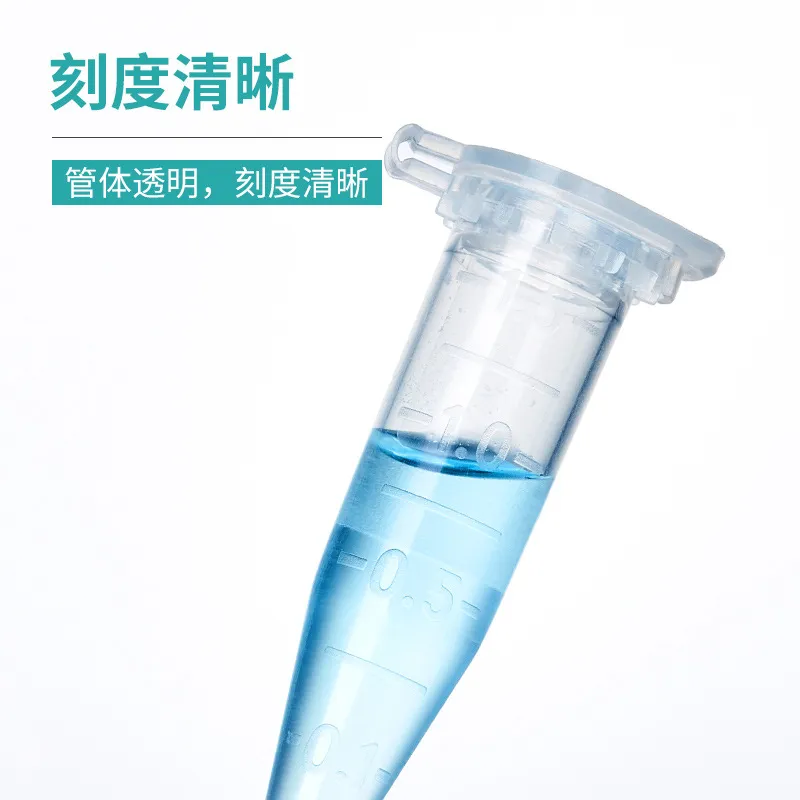

Its slender tubular structure and sharp outlet design enable liquid to flow out in droplet form by controlling the pressure difference inside and outside the dropper. The material of the dropper has also been carefully selected, requiring a certain degree of elasticity and corrosion resistance to ensure that it will not deform or be damaged during repeated use. Some high-end dropper bottles will also use scale markings to more accurately control the volume of droplets.

The head of the Plastic Dropper Bottle, usually made of rubber or silicone, is a key component for controlling liquid flow

By squeezing or releasing the glue head, the pressure inside the dropper can be adjusted to control the dripping speed and quantity of the liquid. The material of the rubber head requires good elasticity and airtightness to ensure that it can respond sensitively to external pressure and avoid liquid leakage.

The design advantages of Plastic Dropper Bottle are reflected in its precision, convenience, and security

Its accuracy can meet the precise measurement requirements of reagents in the laboratory, avoiding the influence of measurement errors on experimental results. Convenience is reflected in its ease of operation and portability, making it suitable for both field research and laboratory operations. Safety is reflected in its airtight design, which can effectively prevent liquid evaporation or leakage, ensuring the safety of users.

In summary, ldpe dropper bottles plays an important role in the field of liquid dispensing due to its exquisite design and outstanding performance. From scientific research to healthcare, from fine chemicals to cosmetics industry, the presence of pet dropper bottles is ubiquitous. With the continuous development of technology, we believe that the future Plastic Dropper Bottle will usher in more innovations in materials, design, and functionality, bringing more convenience and precision to liquid processing.

Plastic Dropper Bottle FAQs

What is the main purpose of Plastic Dropper Bottle?

Plastic Dropper Bottle is designed for precise dispensing of small amounts of liquid, with common uses including:

Laboratory reagents: such as adding indicators, buffer solutions, or standard solutions.

Medical/health products: such as eye drops, essential oils, oral liquids.

Cosmetics: such as essence liquid, perfume sample, nail polish thinner.

Electronic industry: dispensing of soldering flux and precision cleaning agents.

How does the design of the Plastic Dropper Bottle ensure precise control of the liquid?

Key design features:

Cone shaped dropper: controls droplet size through capillary action (typically around 0.05~0.1 mL per droplet).

Squeezing bottle body: Flexible material (such as LDPE) facilitates manual flow control.

Leak proof seal: The dropper fits tightly with the thread of the bottle mouth, making it less likely to leak when inverted.

Scale markings: Some droppers are marked with capacity scales for easy quantitative access.

Why choose Plastic Dropper Bottle instead of Glass Dropper Bottle?

The advantages of Plastic Dropper Bottle include:

Fall resistance: not easily broken, suitable for outdoor or mobile scenarios (such as medical emergency kits).

Lightweight: easy to transport and carry.

Low cost: suitable for one-time or short-term use.

Chemical compatibility: Some plastics (such as PP, HDPE) are resistant to acid, alkali, and organic solvents.

Exception: Strong oxidants (such as concentrated nitric acid) or high-temperature sterilization requirements may still require glass droppers.

What are the requirements for the material of Plastic Dropper Bottle for different liquids?

Material selection should be based on the properties of the liquid:

LDPE (Low Density Polyethylene): Suitable for water-based, weak acid/alkali solutions (such as physiological saline).

HDPE (high-density polyethylene): resistant to slightly corrosive liquids such as alcohol and dilute hydrochloric acid.

PP (polypropylene): resistant to high temperatures (can be sterilized under high pressure) and some organic solvents.

Light resistant bottle (amber/black): protects light sensitive liquids (such as vitamin C solution).

Taboo: Avoid using strong solvents such as acetone and chloroform in ordinary plastic bottles (which may cause swelling or dissolution).

What safety issues should be noted when using Plastic Dropper Bottle?

Important precautions:

Cross contamination: Use specialized droppers for different reagents to avoid mixing.

Drip cleaning: Rinse immediately after use (especially for viscous liquids such as glycerin).

Temperature limit: Avoid high temperature deformation (such as PP bottles can withstand 100 ℃, LDPE can only withstand 60 ℃).

Child safety: If containing toxic liquids, a child safety cover must be provided.

Disposal: Droplets containing chemical residues should be treated as hazardous waste and should not be discarded at will.

-

Reagent Bottle: The Foundation and Guarantee of Chemical ExperimentsNewsJul.16,2025

-

Plastic Vaccine Vials: A Key Container for Ensuring Safe Storage and Transportation of VaccinesNewsJul.16,2025

-

On the Multifunctionality and Application of OEM Spray BottleNewsJul.16,2025

-

Medicine Bottle: The cornerstone of secure storage and distributionNewsJul.16,2025

-

Lab Consumables: The Foundation and Guarantee of Scientific ResearchNewsJul.16,2025