-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Different Types of Spray Bottles Versatile Styles for Home & Industry

- Exploring the diverse world of spray bottle designs and mechanisms

- Advanced materials and engineering innovations in spray technology

- Manufacturer comparison: Technical specifications and performance metrics

- Customization options for specialized industry requirements

- Real-world case studies across healthcare and industrial sectors

- Sustainability considerations in modern spray bottle production

- Selecting appropriate spray bottles for different applications

(different kinds of spray bottles)

Understanding Different Kinds of Spray Bottles

Spray bottles represent far more than simple liquid dispensers - they're precision-engineered solutions addressing specific application requirements. The global spray bottle market, valued at $3.8 billion in 2022, encompasses remarkably diverse designs from household trigger sprays to medical-grade blood collection systems. Industrial chemical sprayers feature chemical-resistant polymers like HDPE or fluoropolymer-lined containers capable of handling corrosive materials, while pharmaceutical versions utilize USP Class VI plastics meeting stringent biocompatibility standards. Cosmetics applications often employ luxurious glass bodies with fine-mist actuators, contrasting sharply with agricultural knapsack sprayers featuring reinforced tanks with 15-20L capacities. Even within medical contexts, different blood collection bottles vary significantly; EDTA tubes prevent coagulation for hematology tests while heparinized versions maintain plasma integrity. The trigger mechanism alone has evolved into multiple specialized formats from continuous spray models to adjustable stream-to-mist configurations that control droplet size from 50-200 microns.

Engineering Breakthroughs in Dispensing Technology

Modern spray technologies incorporate sophisticated engineering principles to enhance performance. High-volume transfer pumps enable continuous spraying without repeated triggering - a critical feature in industrial settings where operators may dispense over 20 liters hourly. Anti-clog nozzle designs now leverage self-cleaning mechanisms and 500-micron filtration systems, virtually eliminating particulate blockage in chemical applications. Premium actuators incorporate silicone valve seals maintaining consistent pressure across 15,000+ actuations. Material science innovations include:

- Multi-layer barrier plastics that extend product shelf-life by reducing oxygen transmission rates by 85%

- Nano-coatings creating hydrophobic surfaces for improved cleanliness

- Conductive polymers preventing static buildup in flammable liquid containers

Precision medical sprayers deliver dosages within ±3% accuracy through micro-engineered pump chambers, far exceeding conventional consumer-grade sprayers' ±15% variance.

Manufacturer Comparison: Technical Specifications

| Manufacturer | Material Options | Max Pressure (PSI) | Chemical Resistance | Spray Patterns | Cycle Life |

|---|---|---|---|---|---|

| US Plastics | HDPE, PETG, PP | 45 | Acids, Solvents | 3 | 25,000 |

| Mayer-RP | LDPE, TPU | 30 | Mild Chemicals | 2 | 15,000 |

| Berlin Packaging | Glass, PET | 28 | Cosmetics | 5 | 10,000 |

| Nemera Medical | Pharma-grade PP | 18 | Bio-compatible | 1 | 50,000+ |

Leading industrial manufacturers like US Plastics invest heavily in automated injection molding systems achieving ±0.15mm dimensional tolerances - critical for leak-free performance in acidic environments. Meanwhile, medical suppliers like Nemera utilize cleanroom production facilities meeting ISO 14644 Class 7 standards where particulate counts remain below 352,000 particles/m³ for sizes ≥0.5µm.

Industry-Specific Customization Options

Specialized sectors demand precisely tailored spray solutions beyond standard offerings. Agriculture requires UV-stabilized orange pigments (Pantone 151C) in containers meeting DOT-39 transportation standards while incorporating anti-siphon valves preventing chemical backflow. Cosmetic brands increasingly specify cobalt-free glass with custom engravings achieving 0.1mm line precision for premium aesthetics. Pharmaceutical applications present unique requirements:

- Blood collection vacuum tubes requiring precise internal coating thickness between 0.8-1.2µm

- Nasal sprayers with dose counters complying with FDA 21 CFR Part 11 electronic record standards

- Child-resistant closures requiring 15N opening force meeting ISO 8317 certification

Industrial users implement RFID-tagged containers integrating with Industry 4.0 inventory systems, while laboratories specify amber-colored vials blocking 99% of UV light between 290-450nm wavelengths.

Application Success Across Industries

Practical implementation case studies demonstrate the critical importance of proper spray bottle selection. A European pharmaceutical company reduced blood sample rejection rates from 4.7% to 0.8% by implementing precisely coated vacuum tubes maintaining consistent anticoagulant distribution. Their quality control process now includes rotational viscometry testing ensuring coating uniformity within ±2% across production batches.

Chemical manufacturer Dow implemented specialized fluoropolymer-lined sprayers for hydrochloric acid application, extending equipment service life from 3 months to 3 years while reducing leakage incidents by 97%. The corrosion-resistant liners maintained integrity despite prolonged exposure to pH <1 solutions.

Agricultural cooperative Land O'Lakes transitioned to UV-stabilized sprayers with integrated flow meters, achieving 18% reduction in pesticide usage through precise application control. Their operators now monitor spray patterns using digital manometers maintaining optimal 30-40 PSI operating pressure.

Sustainability and Environmental Considerations

Material innovation is transforming spray bottle environmental impact. Post-consumer recycled (PCR) content now reaches up to 100% in certain HDPE formulations without compromising structural integrity. Modern designs optimize material usage through:

- Weight reduction initiatives achieving 25% lighter containers versus 2012 baselines

- Monomaterial construction enabling simpler recycling streams

- Refill stations reducing packaging waste by 70% in commercial settings

Lifecycle analyses reveal significant advantages - PET spray bottles generate 35% fewer greenhouse gas emissions versus glass equivalents during transportation. Industrial users increasingly adopt concentrated refill systems where 1L of concentrate replaces 25 standard ready-to-use bottles. Medical facilities implement specialized different blood bottles recycling programs recovering over 85% of materials while ensuring biohazard safety.

Choosing Among Different Types of Spray Bottles

Optimal spray bottle selection requires methodical evaluation of technical parameters against application requirements. Chemical compatibility should be verified through 30-day material immersion tests simulating worst-case conditions. Trigger ergonomics must accommodate expected usage volumes - operators dispensing over 50 actuations hourly require ergonomic levers reducing activation force below 15N. For critical medical applications, verification of USP <661> and <381> compliance proves essential when handling parenteral solutions. Pharmaceutical firms increasingly implement track-and-trace systems requiring scannable 2D matrix codes on individual containers. Environmental factors now demand equal consideration; carbon footprint calculators reveal that switching from virgin PET to 50% PCR content reduces emissions by approximately 280g CO2 equivalent per container. Whether specifying common household models or specialized blood collection systems, every parameter influences performance, safety and sustainability outcomes.

(different kinds of spray bottles)

FAQS on different kinds of spray bottles

Q: What are the different kinds of spray bottles available for household use?

A: Common household spray bottles include trigger sprayers for cleaning solutions, continuous mist bottles for fine sprays, and pressurized aerosol cans for air fresheners or disinfectants.

Q: What are the key differences between different types of spray bottles?

A: Spray bottles vary by mechanism (e.g., manual trigger, pump, or aerosol), material (plastic, glass, or metal), and purpose (cleaning, gardening, or personal care).

Q: How do different kinds of spray bottles work for gardening purposes?

A: Gardening spray bottles often feature adjustable nozzles for misting plants, pressurized tanks for fertilizers, or handheld pump sprays for pest control applications.

Q: What distinguishes different blood bottles used in medical settings?

A: Medical blood bottles differ by additives (e.g., anticoagulants or clot activators) and color-coded tops to indicate specific lab tests like biochemistry or hematology.

Q: Can spray bottles and blood bottles be made from the same materials?

A: While spray bottles are typically plastic, blood bottles require medical-grade glass or specialized plastic to prevent chemical interactions and ensure sample integrity.

-

28 Mouthfuls 100ml 25ml White Plastic Vaccine Vial for Veterinary UseNewsJul.23,2025

-

White Plastic Veterinary Medicine Vaccine Vial for Animal LabsNewsJul.22,2025

-

White 250ml Plastic Clear Vaccine Vial | Lab & Veterinary UseNewsJul.22,2025

-

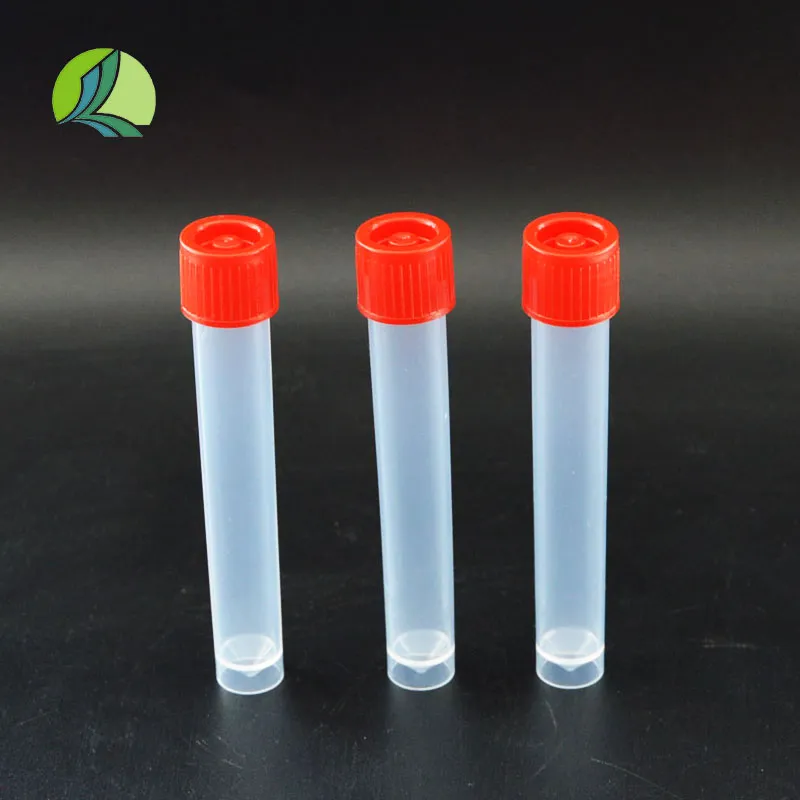

High-Quality Freezer Tubes | Leak-Proof & Durable for Secure StorageNewsJul.21,2025

-

Little Dropper Bottles Wholesale – Leak-Proof, Precise Dispensing Little Plastic Vials & Dropper Tip Bottles for Versatile UseNewsJul.08,2025

-

What is a Culture Plate? Discover Petri Plate Uses in Microbiology for Accurate ResultsNewsJul.08,2025