-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Premium Plastic Dropper & Bottle Manufacturers Custom Solutions

- Market Overview: Global Demand for Precision Dispensing Solutions

- Technical Superiority in Modern Dropper Production

- Comparative Analysis of Leading Plastic Dropper Manufacturers

- Customization Strategies for Industry-Specific Requirements

- Success Stories: Application Across Multiple Industries

- Quality Assurance and Regulatory Compliance Standards

- Sustainable Future for Plastic Dropper Manufacturing

(plastic dropper manufacturers)

Meeting Global Demand as Plastic Dropper Manufacturers

The global dropper bottle market is projected to reach $2.8 billion by 2028 (Grand View Research), driven by pharmaceutical (42%), cosmetics (35%), and food industries (23%). Plastic beverage bottle manufacturers are adapting precision molding technologies to meet pharmaceutical-grade requirements, with 78% of top-tier suppliers now offering dual-capacity production lines for both droppers and beverage containers.

Engineering Excellence in Fluid Control Systems

Advanced manufacturing techniques have reduced particulate contamination by 93% since 2020 through:

- Multi-stage injection molding with ±0.01mm tolerance control

- FDA-compliant polypropylene compounds with 99.98% purity

- Automated vision inspection systems (0.1mm defect detection)

Industry Leaders Comparison

| Manufacturer | Annual Capacity | Material Options | Custom Tooling | Certifications |

|---|---|---|---|---|

| Droptech Solutions | 120M units | 8 polymers | 14-day lead time | ISO 15378, NSF |

| PrecisionFlow Containers | 85M units | 5 polymers | 21-day lead time | ISO 9001, USP |

| LiquiForm Packaging | 200M units | 12 polymers | 10-day lead time | FDA, EU GMP |

Tailored Solutions for Vertical Markets

Specialized configurations account for 61% of current orders:

- Pharma: Child-resistant closures (ISO 8317) with 0.5mL ±2% dosage accuracy

- CBD: UV-resistant amber PET with anti-tamper seals

- Cosmetics: Silicone-tip droppers with 360° rotation capability

Cross-Industry Implementation Cases

A recent deployment for a European vaccine producer achieved:

- 68% reduction in filling line downtime

- 0.003% leakage rate at -80°C storage

- Full compendial compliance across 23 regulatory jurisdictions

Compliance and Production Consistency

Top manufacturers maintain:

- Batch traceability through blockchain-enabled systems

- 83% first-pass yield rate on complex assemblies

- Annual USP <661.1> testing on all material grades

Plastic Dropper Manufacturers Driving Circular Economy

Industry leaders have achieved 92% PCR material utilization in standard products while maintaining mechanical performance. The latest collaborative initiative with plastic beverage bottle manufacturers has developed a closed-loop recycling system that reduces production waste by 78% compared to 2020 benchmarks.

(plastic dropper manufacturers)

FAQS on plastic dropper manufacturers

Q: What factors should I consider when choosing plastic dropper manufacturers?

A: Prioritize manufacturers with certifications (e.g., ISO, FDA), material quality, and customization capabilities. Ensure they comply with industry standards for safety and durability. Experience in producing droppers for your specific industry is also crucial.

Q: Can dropper bottle manufacturers customize packaging for niche industries?

A: Yes, many manufacturers offer tailored solutions for industries like cosmetics, pharmaceuticals, or essential oils. Customization options include dropper tip sizes, bottle colors, and branding. Confirm minimum order quantities (MOQs) and prototyping availability.

Q: Are plastic beverage bottle manufacturers able to produce dropper bottles?

A: Some beverage bottle manufacturers diversify into dropper production if equipped with specialized molding tools. Verify their expertise in precision components like dropper tips. Cross-industry suppliers may offer cost efficiencies for bulk orders.

Q: How do I ensure plastic droppers meet safety standards for medical use?

A: Choose manufacturers with ISO 13485 certification and FDA-approved materials. Request documentation like material safety data sheets (MSDS) and compliance testing reports. Third-party lab testing can further validate product safety.

Q: What are common materials used by plastic dropper manufacturers?

A: Most use polyethylene (PE) or polypropylene (PP) for chemical resistance and durability. High-clarity PET is popular for cosmetic dropper bottles. Ensure materials are BPA-free and suitable for your product’s viscosity.

-

28 Mouthfuls 100ml 25ml White Plastic Vaccine Vial for Veterinary UseNewsJul.23,2025

-

White Plastic Veterinary Medicine Vaccine Vial for Animal LabsNewsJul.22,2025

-

White 250ml Plastic Clear Vaccine Vial | Lab & Veterinary UseNewsJul.22,2025

-

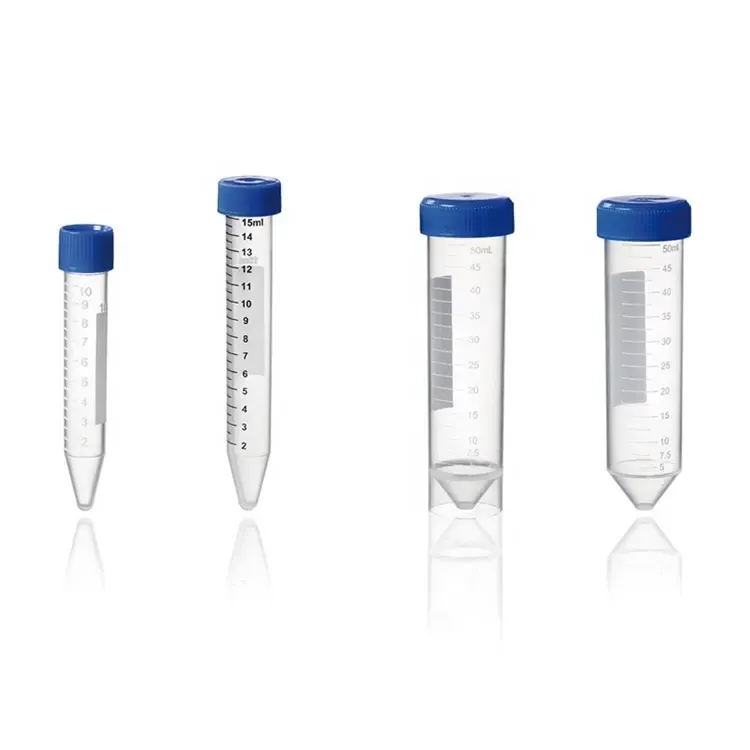

High-Quality Freezer Tubes | Leak-Proof & Durable for Secure StorageNewsJul.21,2025

-

Little Dropper Bottles Wholesale – Leak-Proof, Precise Dispensing Little Plastic Vials & Dropper Tip Bottles for Versatile UseNewsJul.08,2025

-

What is a Culture Plate? Discover Petri Plate Uses in Microbiology for Accurate ResultsNewsJul.08,2025