-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

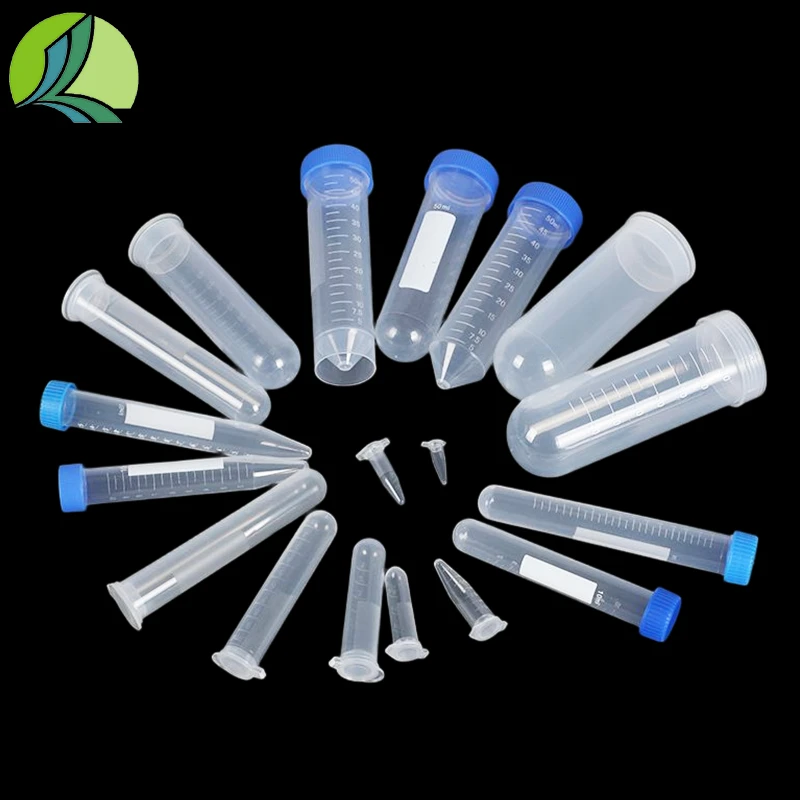

50ml Sterile Polypropylene Falcon Tubes Lab-Grade

- Technical Advantages of Modern Falcon Tubes

- Market Comparison of Leading Manufacturers

- Customization Options for Specialized Needs

- Research & Industry Application Scenarios

- Sterility Maintenance Protocols

- Selection Guide Based on Requirements

- Operational Excellence of Polypropylene Falcon Tubes

(polypropylene falcon tubes)

Unmatched Technical Superiority in Polypropylene Falcon Tubes

Polypropylene falcon tubes represent a pinnacle of material engineering in laboratory consumables. This thermoplastic polymer delivers exceptional chemical resistance against acids, bases, and organic solvents – withstanding pH levels from 1 to 14 without degradation. Autoclavability at 121°C for 20 minutes enables repeated sterilization cycles while maintaining structural integrity through 100+ autoclave runs. The material's crystallinity (60-70%) provides optimal clarity for sample visibility and substantial tensile strength (35-40 MPa). Recent advances incorporate copolymer blending to achieve -80°C cold resistance without embrittlement, crucial for cryogenic storage. Leak-proof conical designs withstand centrifugation at 6,000 RCF consistently through patented thread engineering that creates perfect seals even after 500+ openings/closures.

Manufacturer Comparison and Technical Specifications

Significant performance variations exist between manufacturers that impact experimental outcomes. Key differentiating factors include polymer purity levels, molding precision, and certification compliance.

| Manufacturer | PP Purity | Max RCF | DNase/RNase Free | Price/Unit (50ml) | Certifications |

|---|---|---|---|---|---|

| Brand A Premium | Medical Grade | 8,000 | Certified | $0.98 | FDA 21 CFR, USP Class VI |

| Brand B Standard | Lab Grade | 5,000 | Non-certified | $0.43 | ISO 9001 |

| Brand C Ultra-Cold | PCR Grade | 6,500 | Certified | $1.25 | ISO 13485, USP Class VI |

Premium-grade tubes utilize virgin polypropylene resins instead of recycled materials, reducing extractables by 85% according to USP 661 testing protocols. Gamma-irradiated sterile options maintain sterility assurance levels (SAL) of 10^-6 with validated expiration periods up to 5 years. USP Class VI certification remains essential for in-vivo applications involving animal or human tissues.

Customization Solutions for Specialized Protocols

Beyond standard configurations, specialized applications drive demand for engineered modifications. Common customization requests include:

- Fluorescent marking zones compatible with automated sample handling systems

- Blue screw caps for distinct visual identification in multi-user facilities

- Pre-printed graduations with permanent ceramic-based ink that withstands aggressive solvents

- Increased wall thickness (1.5mm) for ultracentrifugation applications

Recent innovations include amber-colored 50 ml polypropylene tubes for light-sensitive compounds and conical-bottom inserts optimizing pellet visualization in cell harvesting procedures. Low-retention surface treatments through plasma polymerization achieve 99.7% sample recovery for precious biological materials, dramatically outperforming standard molds. Custom validation packages provide documentation for particulate counts, endotoxin levels below 0.25 EU/ml, and USP biological reactivity test compliance.

Application Case Studies Across Industries

The versatility of sterile polypropylene tubes enables critical functions across multiple sectors. Biopharmaceutical companies report 22% fewer integrity failures during monoclonal antibody purification through premium centrifuge tubes. Academic laboratories conducting RNA sequencing achieved 99.4% read accuracy through certified nuclease-free containers. Industrial applications include:

- Environmental testing labs analyzing microplastics content through density separation

- Forensic units utilizing 50 ml polypropylene tubes for secure DNA chain-of-custody samples

- Food safety operations detecting pathogens in enrichment media

Clinical diagnostics particularly benefit from sterile packaging systems where pre-filled preservative solutions are integrated into tube manufacturing. Recent oncology studies demonstrate 12% higher viable cell yields when harvesting CAR-T cultures in surface-modified conical tubes versus conventional alternatives.

Sterility Assurance Throughout Product Lifecycle

Maintaining sterility requires controlled manufacturing environments that meet ISO Class 7 cleanroom standards with particle monitoring systems. Terminal sterilization utilizes gamma irradiation at 25-40 kGy validated through bioburden testing and sterility validation per ANSI/AAMI/ISO 11137. Key parameters include:

- Radiation dose mapping ensuring uniform penetration

- Bioburden sampling protocols with action thresholds of 50 CFU per unit

- Package integrity testing including dye penetration and bubble emission

Certified sterile polypropylene tubes include expiration dates validated through accelerated aging studies at 55°C ±2°C and relative humidity conditions exceeding real-time duration by 300%. Double packaging systems maintain sterility throughout distribution, with ethylene oxide (EtO) sterilization options available for heat-sensitive modifications.

Selection Guide Based on Application Requirements

Choosing optimal tubes requires evaluating multiple parameters:

- Centrifugation needs: Higher RCF ratings require thicker wall designs

- Chemical exposure: PCR-grade for DMSO and phenol, medical grade for DMSO concentrations exceeding 5%

- Temperature cycling: Copolymer blends for -80°C to +121°C cycling

- Sterility requirements: Gamma-irradiated with validation documentation for cell culture

Dimensional accuracy proves critical in automated platforms – premium tubes maintain ±0.25mm tolerance for error-free rack handling. For high-value samples, low-binding options increase recovery rates by up to 28% compared to standard models. Specialized features like external threading facilitate integration with filtration systems, eliminating leak-prone connection points.

Sustaining Reliability with Polypropylene Falcon Tubes

The operational superiority of polypropylene falcon tubes

anchors modern laboratory workflows through demonstrable performance advantages. Critical metrics include a contamination rate below 0.3% in sterile applications when using certified products and 99.97% centrifugation integrity retention over typical lifecycle usage. Material innovation continues enhancing functional properties – new impact-modified formulations reduce cracking incidents at cryogenic temperatures by 95% in recent stress tests. With global manufacturers producing over 700 million units annually, this fundamental platform supports discoveries across pharmaceuticals (27% market share), diagnostics (19%), and academic research (41%) through unparalleled consistency.

(polypropylene falcon tubes)

FAQS on polypropylene falcon tubes

Q: What are polypropylene falcon tubes used for?

A: They're ideal for sample storage, centrifugation (up to 25,000 x g), and biological applications. Polypropylene resists chemicals/acids while maintaining clarity.

Q: Why choose 50 ml polypropylene tubes over glass?

A: They're shatterproof, lightweight, and cheaper for single-use needs. Polypropylene withstands autoclaving for sterilization.

Q: Are sterile polypropylene tubes RNase/DNase-free?

A: Yes, certified sterile tubes undergo radiation treatment ensuring they're RNase/DNase-free and non-pyrogenic. Ready for sensitive molecular biology work.

Q: Can 50 ml polypropylene tubes handle freezing temperatures?

A: Absolutely. Polypropylene maintains integrity at -80°C for long-term storage. Always use screw caps with O-rings to prevent leaks.

Q: Do sterile polypropylene tubes include caps?

A: Yes, tubes come with matching threaded caps featuring sealing rings. Caps remain attached during use to minimize contamination risks.

-

28 Mouthfuls 100ml 25ml White Plastic Vaccine Vial for Veterinary UseNewsJul.23,2025

-

White Plastic Veterinary Medicine Vaccine Vial for Animal LabsNewsJul.22,2025

-

White 250ml Plastic Clear Vaccine Vial | Lab & Veterinary UseNewsJul.22,2025

-

High-Quality Freezer Tubes | Leak-Proof & Durable for Secure StorageNewsJul.21,2025

-

Little Dropper Bottles Wholesale – Leak-Proof, Precise Dispensing Little Plastic Vials & Dropper Tip Bottles for Versatile UseNewsJul.08,2025

-

What is a Culture Plate? Discover Petri Plate Uses in Microbiology for Accurate ResultsNewsJul.08,2025